HOW TO CHOOSE THE RIGHT PASTE FILLING MACHINE

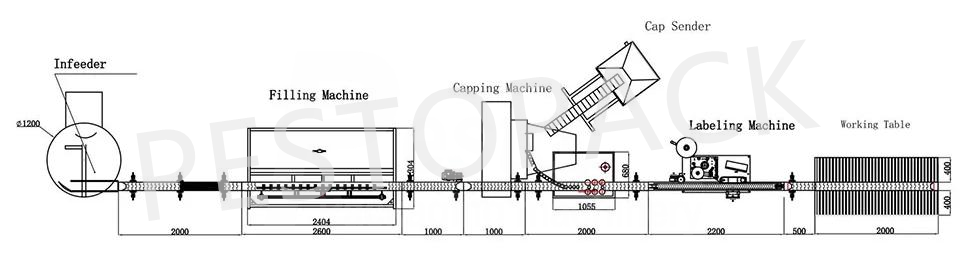

Choosing the right automatic paste filling machine involves considering several factors. Here are some steps to guide you in selecting the appropriate machine:

1. Determine your production requirements: Assess the volume of paste you plan to produce. Consider factors such as batch size, production capacity, and expected growth. This will help you determine the automatic paste filling machine's speed and capacity requirements.

2. Identify the filling method: Different filling methods are available, including gravity filling, piston filling, and vacuum filling. Evaluate the viscosity and foaming characteristics of your paste to determine the most suitable filling method. For example, if your paste has high viscosity, a rotor pump filling machine is more suitable.

3. Consider container types and sizes: Determine the types and sizes of containers you will be using for your paste. Ensure the automatic paste filling machine can accommodate the specific containers, whether they are bottles, jars, or tubes. Consider factors such as bottle neck sizes, shapes, and closure types.

4. Evaluate machine features: Look for features that align with your specific needs. Some key considerations include adjustable filling volumes, accuracy, ease of operation, ease of cleaning and maintenance, and compatibility with different paste formulations.

5. Quality and reliability: Choose a reputable manufacturer known for producing reliable and high-quality filling machines. Ensure the automatic paste filling equipment is made from durable materials to withstand the demands of spaste production. Pestopack is a quality and reliability automatic paste filling machine manufacturer which is to be trused.

6. Cost and budget: Consider your budget and the overall cost of the automatic paste filling system, including any necessary accessories, spare parts, and ongoing maintenance.

WORKING PRINCIPLE OF OUR AUTOMATIC PASTE FILLING MACHINE

Automatic paste filling machine normally use rotor pump. The working principle of a rotor pump filling machine involves a rotating mechanism that displaces the liquid from a reservoir to the containers. Here's an overview of how it works:

Reservoir and Hopper:

The machine is equipped with a reservoir or hopper where the liquid to be filled is stored. The hopper may include an agitator or mixing mechanism to maintain uniform consistency, especially for viscous liquids.

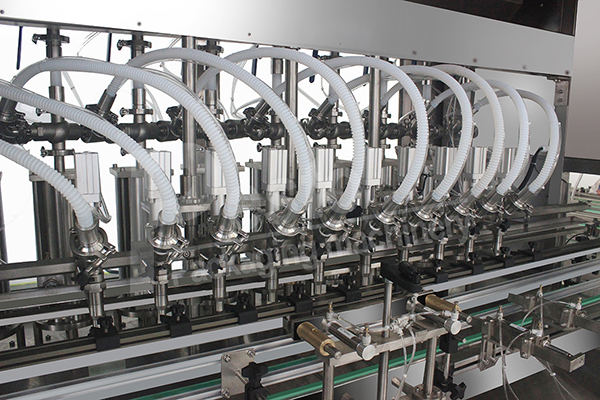

Rotary Pump Mechanism:

The key component of the machine is the rotary pump mechanism. This consists of a series of rotating lobes, gears, or pistons inside a casing. As the pump rotates, it creates chambers that expand and contract, drawing in and displacing the liquid.

Filling Nozzle:

The machine is equipped with filling nozzles that are positioned above the containers to be filled.

Filling Cycle:

The filling cycle begins with an empty container being positioned under the filling nozzle. The nozzle is then lowered into the container.

Filling Process:

As the pump rotates, the liquid from the reservoir is drawn into the pump's chambers. As the chambers rotate, the liquid is pushed toward the discharge side of the pump.

Discharge:

The liquid is displaced from the pump's chambers and travels through the pump's outlet pipe toward the filling nozzle.

Filling Operation:

The liquid flows through the filling nozzle and into the container. The filling nozzle usually has a valve mechanism that opens during the filling process and closes once the desired fill level is reached.

Fill Level Control:

The fill level is controlled based on the pump's rotation and the nozzle's opening and closing mechanism. This ensures accurate and consistent fill volumes.

Container Removal:

Once the filling cycle is complete, the nozzle retracts, and the filled container is moved away from the filling station

HOW TO MAINTAIN AND CLEAN OUR PASTE FILLING MACHINE

Maintaining and cleaning a liquid paste filling machine is essential to ensure its proper functioning, longevity, and hygiene. Here are Pestopack's guidelines for maintaining and cleaning a paste filling machine:

Regular Inspection

Conduct routine inspections of the machine to identify any signs of wear, damage, or loose parts. Check for leaks, worn seals, damaged valves, or any other issues that may affect the machine's performance. Promptly address any identified problems.

Lubrication

Some parts of the liquid paste filling machine require lubrication to ensure smooth operation and minimize friction. Follow our recommendations for the appropriate lubricants and the recommended intervals for lubrication. Avoid over-lubrication, as it can lead to contamination.

Cleaning

Establish a regular cleaning schedule for the automatic paste filler machine. This includes both routine cleaning between production runs and thorough cleaning at scheduled intervals.

Replace Wearable Parts

Over time, certain parts of the automatic paste filling machine may wear out and require replacement. These parts may include seals, gaskets, o-rings, filters, and other components.

Operator Training

Ensure that operators are properly trained in the operation, maintenance, and cleaning procedures for the paste filling machine. This will help prevent errors, reduce downtime, and promote safe and efficient operation.

Documentation and Records

Maintain records of maintenance activities, cleaning schedules, and any repairs or replacements performed on the machine. This documentation can be useful for tracking maintenance history, identifying recurring issues, and ensuring compliance with regulatory requirements.

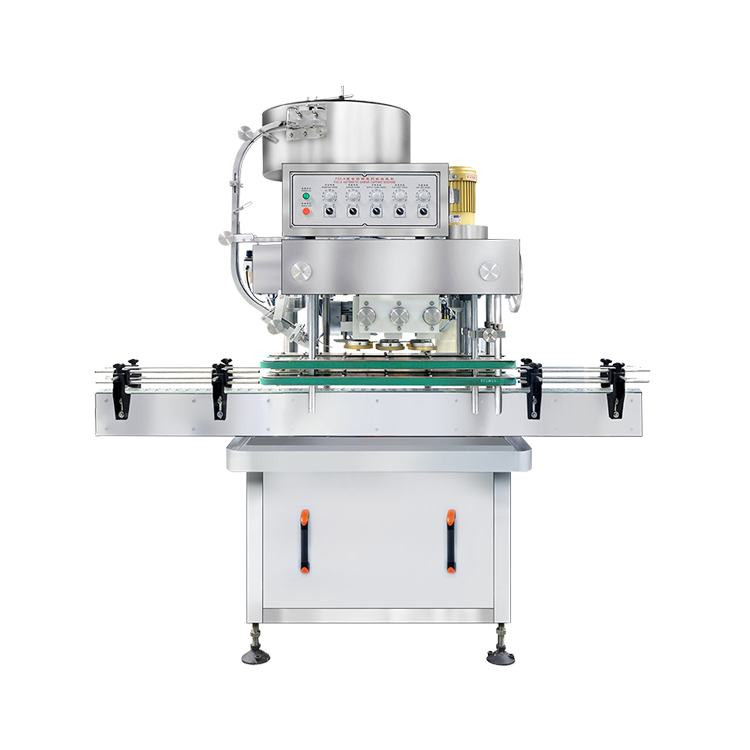

HOW TO ADJUST PASTE FILLING MACHINE TO FIT DIFFERENT BOTTLE SIZES

Adjusting a liquid paste filling machine to accommodate different bottle sizes involves making changes to the machine's settings and components. Here's the guide on how to adjust our paste filling machine for different bottle sizes, it is a easy process for adjustment:

Bottle Height Adjustment

The paste liquid filling machine has mechanisms to adjust the height of the filling nozzles and the bottle platform. Raise or lower the filling nozzles and bottle platform to match the height of the bottles being filled. This ensures that the nozzles are positioned correctly for accurate filling without causing spills or splashing.

Bottle Diameter Adjustment

We have clamps in paste filling equipment to accommodate different bottle diameters. Locate clamps and adjust them to fit the specific bottle diameter. Ensure a snug fit to hold the bottles securely in place during the filling process.

Filling Volume Adjustment

Different bottle sizes require varying filling volumes. Adjust the filling volume settings on the paste filling machine to match the desired volume for the specific bottle size. This can be done through our machine's touch screen easily.

Conveyor System

You also need to adjust conveyor to accommodate different bottle sizes. This ensures smooth and stable movement of the bottles throughout the filling process.

Test and Fine-tuning

After making the necessary adjustments, it's important to test the liquid paste filling machine with the new bottle size. Run a test batch of bottles through the machine to ensure that the filling process is accurate, consistent, and without any issues. Monitor the filling levels and check for any leaks or spills. Make further adjustments if needed to achieve the desired results.

English

العربية

Français

Русский

Español

Português

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

қазақ

हिन्दी

فارسی

Kiswahili

українська

Հայերեն

עברית

বাংলা

සිංහල

Oʻzbekcha

Azərbaycan dili

Български

ქართული

guarani

ગુજરાતી

Hausa

Igbo

ಕನ್ನಡ

Kinyarwanda

Kurdî

Кыргызча

Oluganda

മലയാളം

मराठी

Afaan Oromoo

ਪੰਜਾਬੀ

Runasimi

chiShona

Soomaali

Тоҷикӣ

తెలుగు

ትግንያውያን

Türkmençe

Yorùbá

isiZulu