Introduction

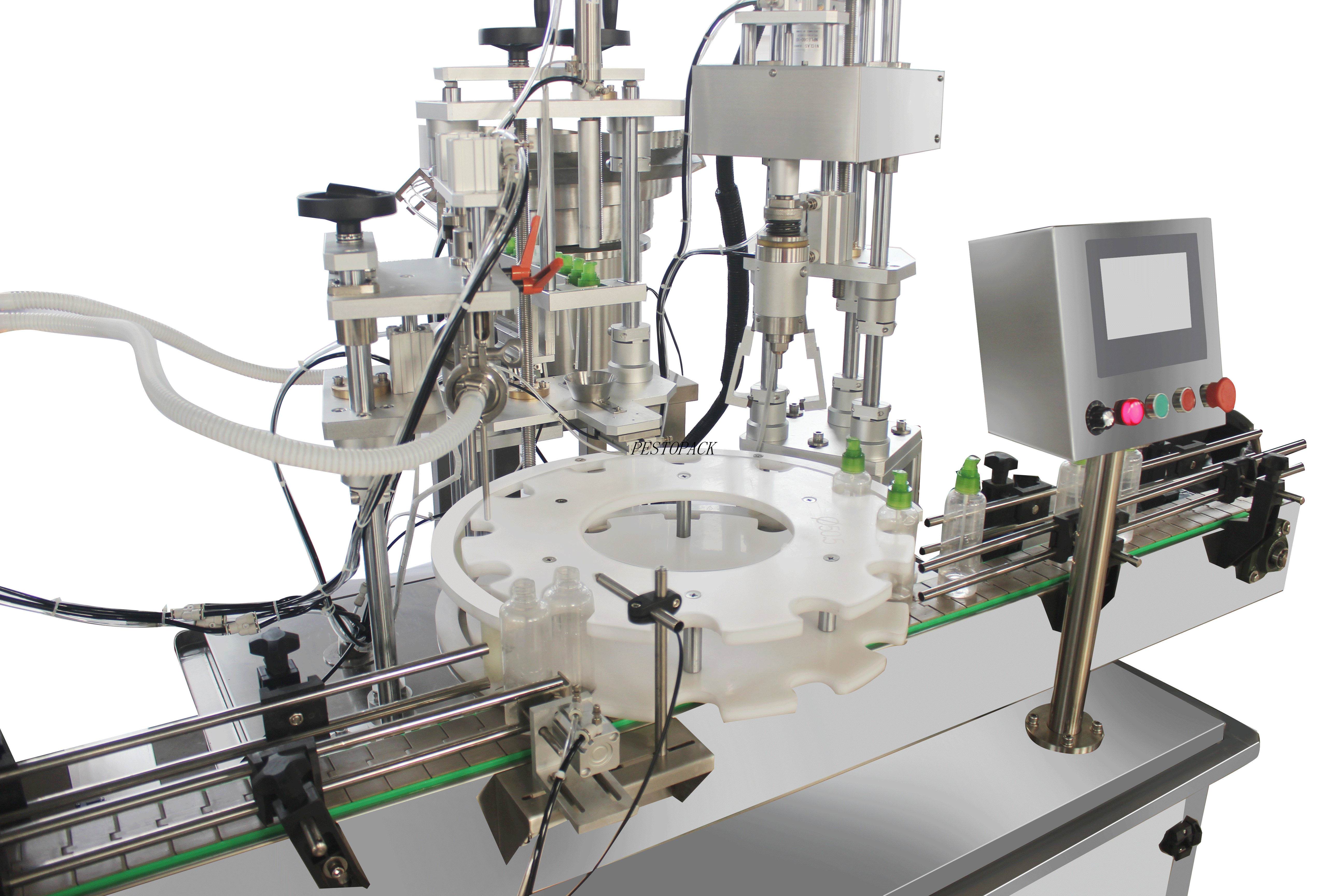

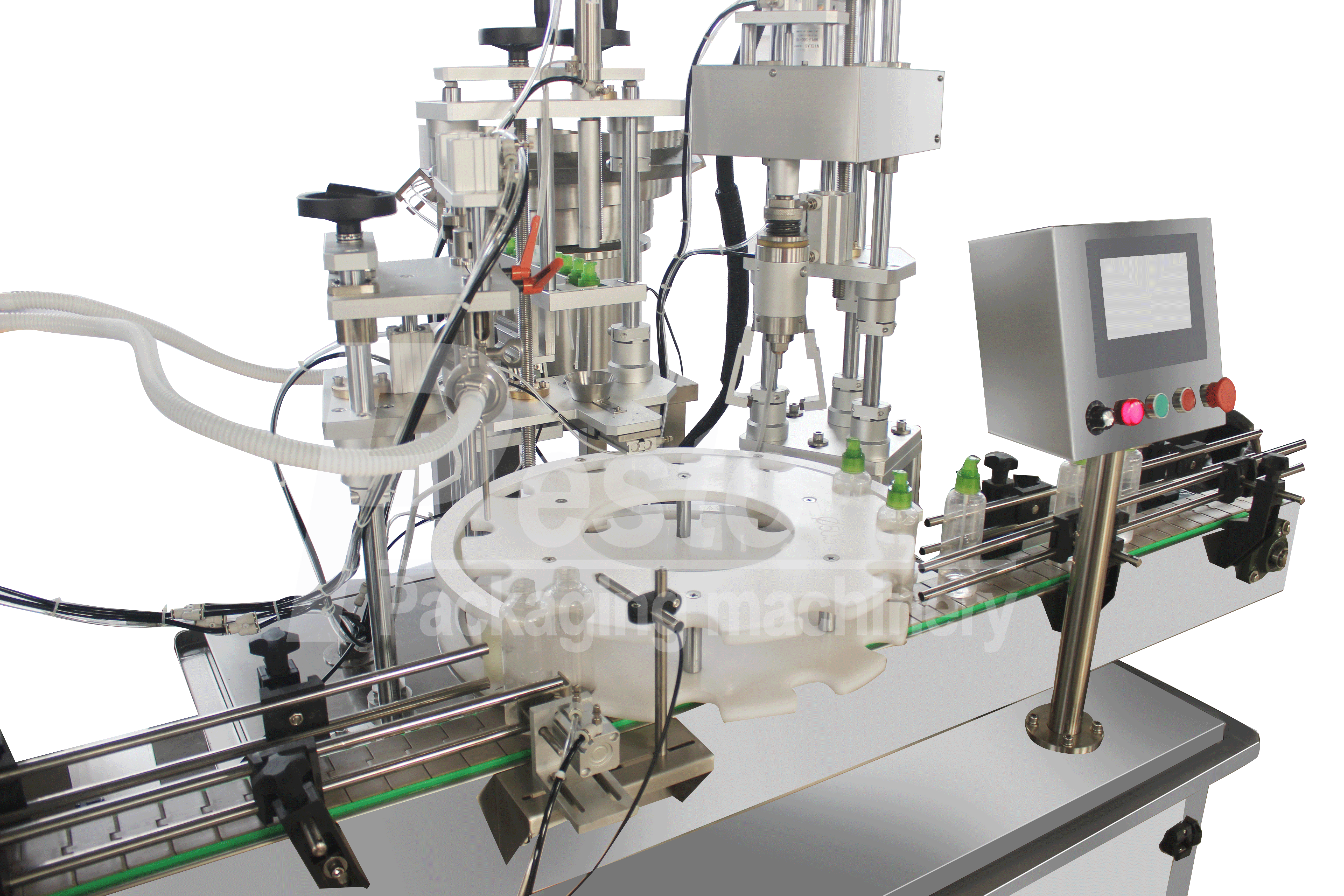

Glue filling machines have a wide range of applications across industries, from packaging to medical devices. At Pestopack, we design and manufacture advanced glue filling and capping machines that ensure precision, efficiency, and safety. Our equipment integrates filling and capping into one automated process, delivering consistent results while reducing manual handling and errors.

Applications of Glue Filling Machines

1. Packaging Industry

Glue and adhesives are widely used in sealing cartons, boxes, and bottles. With precise application, packaging integrity is improved, ensuring product safety during transport and storage.

2. Construction Industry

Adhesives bond tiles, flooring, wood, and other building materials, contributing to structural strength and long-lasting installations.

3. Woodworking and Furniture Manufacturing

Wood components are securely bonded using glue, producing durable furniture and wooden products with superior craftsmanship.

4. Automotive Industry

Automotive manufacturers rely on adhesive application to bond windshields, headlights, and interior components, ensuring safety and durability under stress.

5. Electronics Manufacturing

In electronics, adhesives play a critical role in bonding and protecting delicate components, improving device stability and longevity.

6. Medical Device Manufacturing

Medical equipment assembly often requires precise adhesive application to secure and seal components, meeting strict quality and safety standards.

English

العربية

Français

Русский

Español

Português

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

қазақ

हिन्दी

فارسی

Kiswahili

українська

Հայերեն

עברית

বাংলা

සිංහල

Oʻzbekcha

Azərbaycan dili

Български

ქართული

guarani

ગુજરાતી

Hausa

Igbo

ಕನ್ನಡ

Kinyarwanda

Kurdî

Кыргызча

Oluganda

മലയാളം

मराठी

Afaan Oromoo

ਪੰਜਾਬੀ

Runasimi

chiShona

Soomaali

Тоҷикӣ

తెలుగు

ትግንያውያን

Türkmençe

Yorùbá

isiZulu