VIDEO OF JERRY CAN FILLING MACHINE

JERRY CAN FILLING MACHINE FOR SALE

Liquid processing operations require jerry can filling equipment to fill a wide range of containers. Jerrycans can be used in a wide range of industries to carry and tote liquids. From 5 liters to 30 liters, we manage your jerrycans with screw caps, flexspouts or push-on caps. We can design and build your jerry can filling machine or even engineer an entire jerry can filling system to meet your container and production requirements. Jerry can filling machine is made of 304 stainless steel and designed to fill a wide variety of products into various containers sizes and shapes. It is the ideal solution in chemical filling machine industry to fill any homogeneous liquid products, including food, fragile, abrasive, corrosive or inflammable products.

FEATURES OF JERRY CAN FILLING MACHINE

1. This jerry can filling machine adopts PLC, touch screen control panel, convenient to adjust.

2. Each filling head has the weigh and feedback system. Each filling head can be regulated.

3. Photoelectric sensor, approximate switch and other electric elements are the international famous brand. No container no filling. The main host can trigger the alarm if there is any container blocked.

4. Easy adjust filling volume in touch screen.

5. Long life – durable machine structure built in 304 stainless steel.

6. Extremely accurate filling – Weighfilling technology is not impacted by temperature change.

TECHNICAL PARAMETERS

| Filling heads | 2 | 4 | 6 | 8 |

Production speed

(bottles/hour) | 350(30KG) | 450(30KG) | 520(30KG) | 600(30KG) |

| Filling accuracy | ±0.5% |

| Filling range | 4-30L |

| Suitable bottles | Length: 160-3600mm; Width:100-300mm

Height:250-500mm; Neck diameter:≥Φ40mm |

| Power | 2KW | 2KW | 2KW | 2.5KW |

| Power source | 220/380V 50/60Hz |

| Air source | 0.6Mpa |

| Dimension(mm) | 2000*1700*2300 | 2500*1700*2300 | 3500*1700*2300 | 4500*1700*2300 |

BENEFITES OF JERRY CAN FILLING SYSTEM

High cost effective

Automatic jerry can filling system is much higher effective than semi automatic and manual operation. That is an ideal machine for production.

User freindly

Easily controlled by PLC and touch screen operation. Parameter data can be adjusted and saved in touch screen. Only one worker can operation without complex process.

Easy cleaning

The jerry can filling machine without dead angle. Connection parts use quick coupling. No worries for cleaning.

Wide application

This jerry can filling system is mainly for any homogeneous liquid products including food, fragile, abrasive, corrosive or inflammable products.

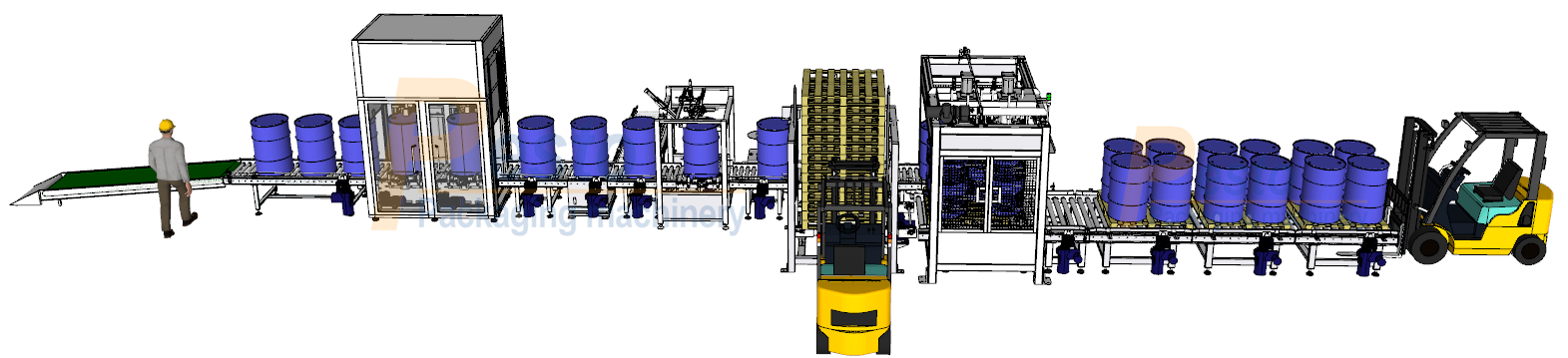

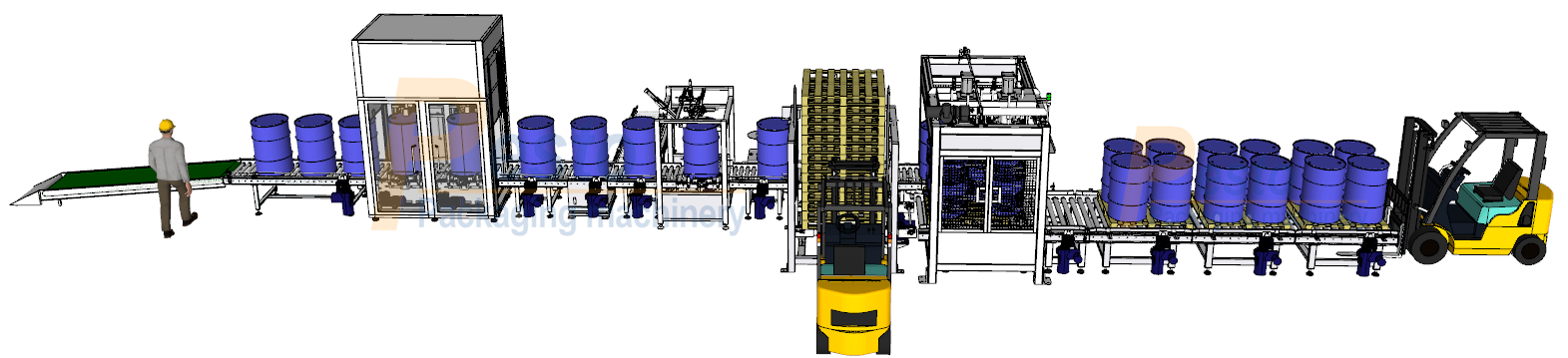

LAYOUT OF JERRY CAN FILLING MACHINE

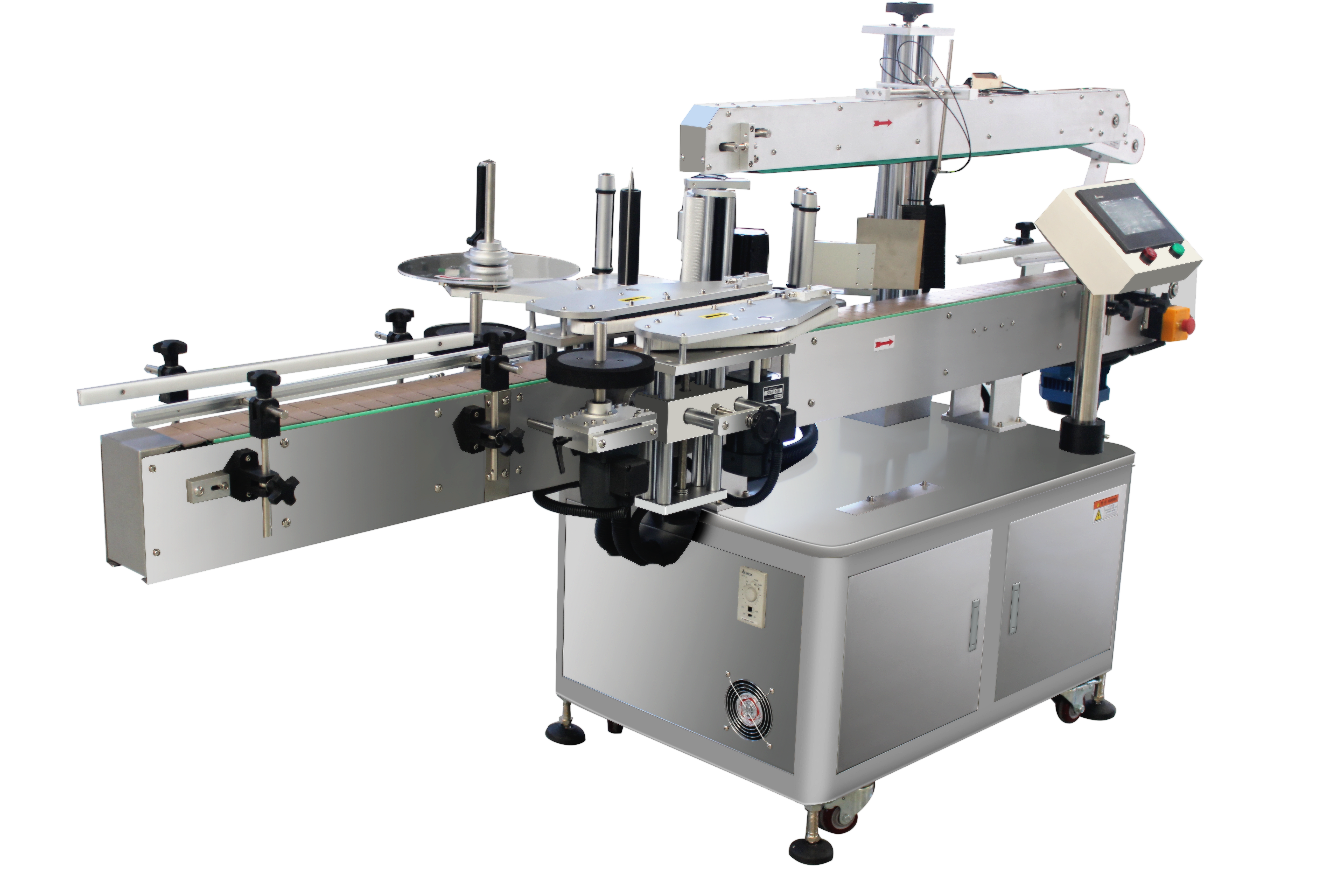

We customize the entire jerry can filling line to match your specific product requirements, production volume, and facility layout. Pestopack provides support throughout the entire process, from initial design and equipment selection to installation, testing, and ongoing maintenance. We ensure that all components in the filling line, including conveyors, jerry can filling machines, capping machines, labeling machines, and more, are integrated harmoniously. This optimization enhances overall efficiency and minimizes bottlenecks.

English

العربية

Français

Русский

Español

Português

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

қазақ

हिन्दी

فارسی

Kiswahili

українська

Հայերեն

עברית

বাংলা

සිංහල

Oʻzbekcha

Azərbaycan dili

Български

ქართული

guarani

ગુજરાતી

Hausa

Igbo

ಕನ್ನಡ

Kinyarwanda

Kurdî

Кыргызча

Oluganda

മലയാളം

मराठी

Afaan Oromoo

ਪੰਜਾਬੀ

Runasimi

chiShona

Soomaali

Тоҷикӣ

తెలుగు

ትግንያውያን

Türkmençe

Yorùbá

isiZulu