VIDEO OF DRUM FILLING MACHINE

DRUM FILLING MACHINE FOR SALE

The automatic drum filling machine for sale enable accurate control and measurement of liquid materials in an industrial environment. Whether automatic, semi-automatic, or manual, the drum filler machine is designed to provide an increased level of automation during the filling process. Our drum filling equipment and paint filling machine provide efficient, precise, and repeatable results. A variety of drum filling machines for sale that provide accurate measurement, improved control, and increased automation are available to integrate into the manufacturing process. The drum filling system provides accurate, low maintenance, no-drip filling of liquid to viscous products into cans, pails, drums and totes for 100kg-300kg.

FEATURES OF DRUM FILLING MACHINE

1. Auto Induction Filling Inlet Mouth

Our drum filling machine is equipped with an innovative auto-induction feature. It automatically detects and positions the filling inlet mouth, streamlining the filling process. As soon as the mouth is correctly aligned, the filling head smoothly descends to begin the filling operation, ensuring precision and efficiency.

2. Variable Filling Speed for Enhanced Accuracy

One standout feature of our drum filling equipment is its ability to adjust the filling speed dynamically. It starts with a rapid fill rate and gradually slows down as it approaches the desired fill level. This intelligent design minimizes the chances of overfilling or underfilling, resulting in exceptional filling accuracy.

3. Premium Stainless Steel Frame with Mirror Polish

The drum filling system boasts a high-quality stainless steel frame with a flawless mirror polish finish. This construction not only ensures durability and longevity but also eliminates burrs and welding lines. The sleek and hygienic design is ideal for industries with stringent cleanliness standards.

4. Weighing Filling with Touch Screen Control

Precision is at your fingertips with our drum filling system. The weighing filling mechanism allows for accurate and adjustable filling volumes. Operators can easily set and fine-tune the desired fill quantity via the intuitive touch screen interface, providing full control over the filling process.

5. Top-Quality Brand Filling Tube

Safety and longevity are guaranteed with our drum filling machine. We use top-tier brand filling tubes that meet the highest industry standards. These tubes are not only safe for handling various products but also ensure a longer working life, reducing maintenance costs.

6. Tidy Wiring System with Independent Electronic Cabinet

Safety and aesthetics are paramount in our design. The wiring system in our drum filling machine is meticulously organized, and each wire is tagged for clarity. All electronics are housed in an independent cabinet, enhancing safety, and giving the machine a clean and professional appearance.

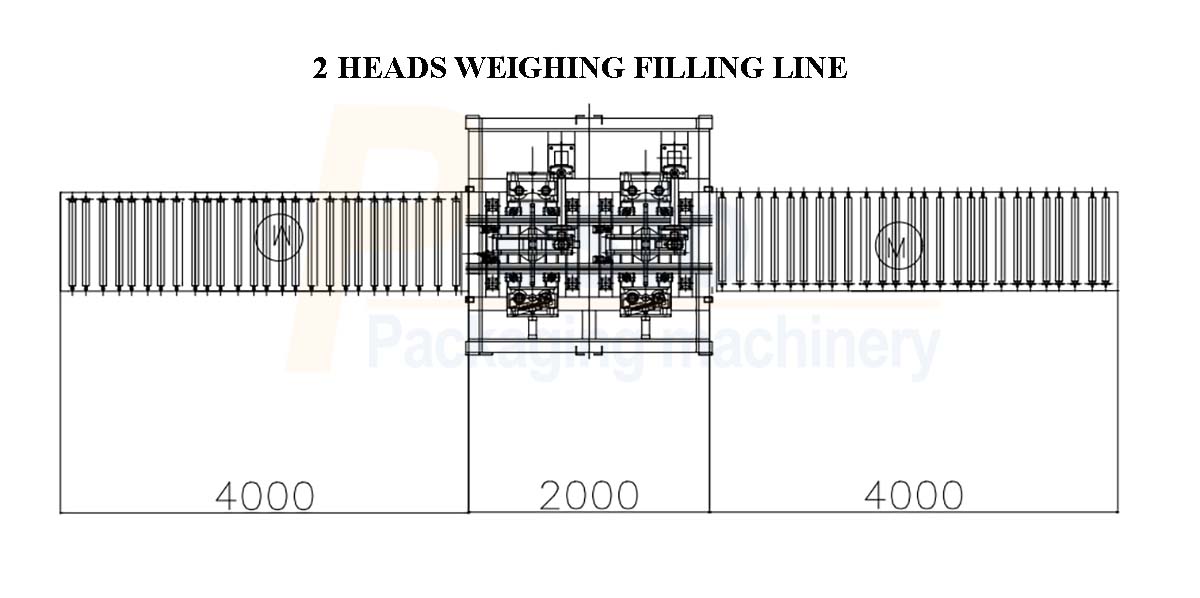

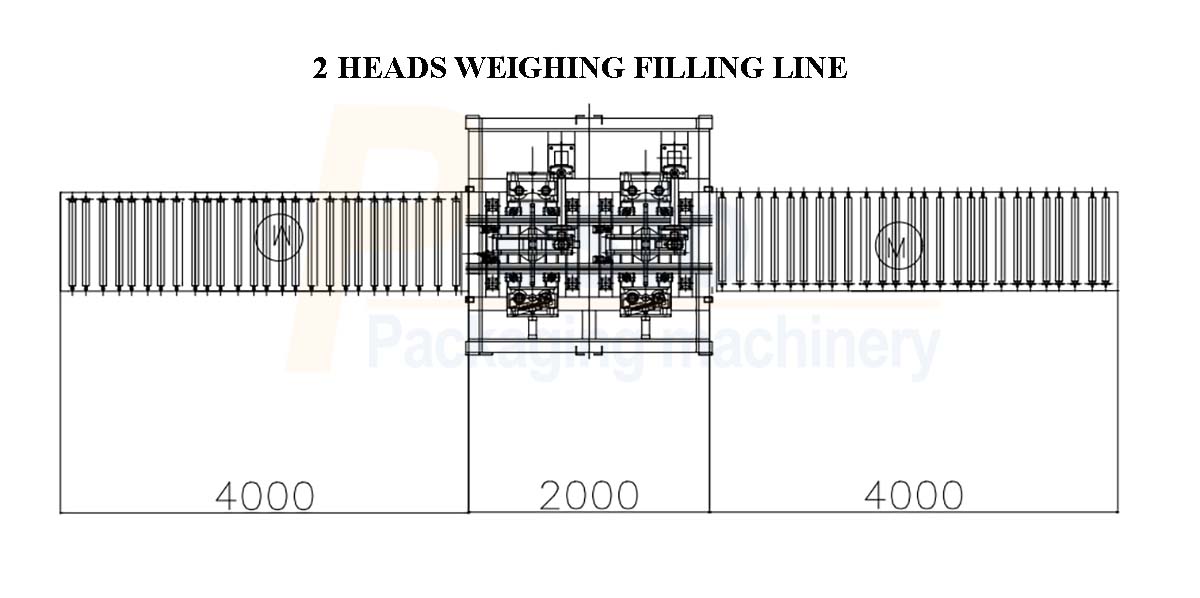

TECHNICAL PARAMETERS

Filling inlet mouth diameter | ≥50mm(Filling nozzle can be made according to the barrel inlet mouth) |

Barrel diameter | ∅500mm~∅700mm(Special barrel can be made) |

Filling range | 100-300kg |

Filling accuracy | ≤ +-0.1% |

Filling head | 2 |

Production speed | ≥60 barrels/hour |

Weight controller | Yes |

Conveyor roller | Yes |

Power | 2.5KW |

Air source | 0.5MPa clean steady air |

Power supply | AC380V 50HZ Three Phase no limitation |

Working temperature | -10ºC -- 50ºC |

Working humidity | <95% (No Condensation) |

Weight | 1600kg |

Dimension | 2000(L)*2300(W)*3000(H)mm |

DETAILES OF DRUM FILLING MACHINE

Our advanced drum filling machine is designed to revolutionize your filling process with precision, efficiency, and safety. The drum filling system is engineered to provide precise measurements, minimizing product wastage and ensuring consistent fill levels in every drum. PLC control unit allows for precise, customizable, and user-friendly operation. Our drum filling machine is equipped with a comprehensive range of safety features like emergency stop buttons, safety frame, robust construction and materials.

BENEFITS OF DRUM FILLING EQUIPMENT

High cost effective

The drum filling equipment is much higher effective than semi automatic and manual operation. That is an ideal drum filling machine for production.

User freindly

The drum filler is easily controlled by PLC and touch screen operation. Parameter data can be adjusted and saved in touch screen. Only one worker can operation without complex process.

Easy cleaning

This drum filling equipment without dead angle. Connection parts use quick coupling. No worries for cleaning.

Wide application

This drum filling equipment is mainly for any homogeneous liquid products including food, fragile, abrasive, corrosive or inflammable products.

INSTALL A COMPLETE DRUM FILLING SYSTEM

At PESTOPACK, we understand that every liquid packaging operation is unique, and that's why we offer a comprehensive range of customization options for your drum filling system. Our goal is to provide you with a tailored drum filling solution that perfectly fits your needs, ensuring optimal efficiency and performance in your production processes.

1. Wide Range of Configurations

PESTOPACK offers a diverse selection of configurations for your drum filling line. Whether you need a semi-automatic system for smaller-scale operations or a fully automated production line for high-volume production, we have the right setup for you. Our range includes single-head and multi-head filling systems, as well as options for inline capping, labeling, and more.

2. Settings to Suit Your Requirements

We understand that different products and industries have unique requirements. Our drum filling systems can be easily customized to accommodate various drum sizes, fill volumes, and fill types. From hazardous chemicals to food-grade liquids, we ensure that our drum filling machine settings are adaptable to meet your specific needs.

3. Size Options to Fit Your Space

Space constraints in your facility are never an issue with PESTOPACK. We offer various size options for our drum filling systems, allowing you to choose a compact unit for smaller production areas or a larger system for high-capacity manufacturing.

4. Professional Guidance from Our Team

Our experienced team of professionals is dedicated to helping you make the right choices. We collaborate with you to assess your production requirements and challenges, guiding you through the selection process. Whether you're setting up a new drum filling line or upgrading an existing one, our expertise ensures you get the best achievable results.

5. Quality and Reliability Guaranteed

PESTOPACK is synonymous with quality and reliability. Our drum filling equipment is constructed using the highgrade materials and state-of-the-art technology. With our drum filling system in place, you can count on consistent and accurate filling, reducing product wastage and enhancing your operational efficiency.

English

العربية

Français

Русский

Español

Português

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

қазақ

हिन्दी

فارسی

Kiswahili

українська

Հայերեն

עברית

বাংলা

සිංහල

Oʻzbekcha

Azərbaycan dili

Български

ქართული

guarani

ગુજરાતી

Hausa

Igbo

ಕನ್ನಡ

Kinyarwanda

Kurdî

Кыргызча

Oluganda

മലയാളം

मराठी

Afaan Oromoo

ਪੰਜਾਬੀ

Runasimi

chiShona

Soomaali

Тоҷикӣ

తెలుగు

ትግንያውያን

Türkmençe

Yorùbá

isiZulu