Hand Sanitizer Filling Machine Application

Hand Sanitizer Filling Machine Application

Hand sanitizer, also known as hand antiseptic or hand rub, is a critical hygiene product used worldwide. Its primary role is to kill bacteria, viruses, and fungi on the skin, preventing the spread of infections. Since the global pandemic, demand for hand sanitizers has skyrocketed in both consumer and industrial markets.

Hand sanitizers are generally classified into two categories:

Alcohol-based sanitizers – containing 60–75% ethanol or isopropyl alcohol, widely recognized for effectiveness against pathogens.

Non-alcohol sanitizers – containing benzalkonium chloride or triclosan as active ingredients.

Both forms require precise and hygienic packaging to ensure safety, stability, and compliance with international GMP standards.

Why Hand Sanitizer Filling Machines Are Essential

Manually filling bottles is inefficient, inconsistent, and prone to contamination. A hand sanitizer filling machine eliminates these risks by automating the process.

Key reasons why manufacturers adopt filling machines:

Accuracy: Prevents overfilling and product loss.

Speed: Meets high production demands.

Consistency: Ensures every bottle meets the same quality standard.

Hygiene: Minimizes human contact, ensuring safe and contamination-free filling.

Flexibility: Handles multiple bottle sizes, shapes, and cap styles.

How Our Hand Sanitizer Filling Machine Fits Your Products

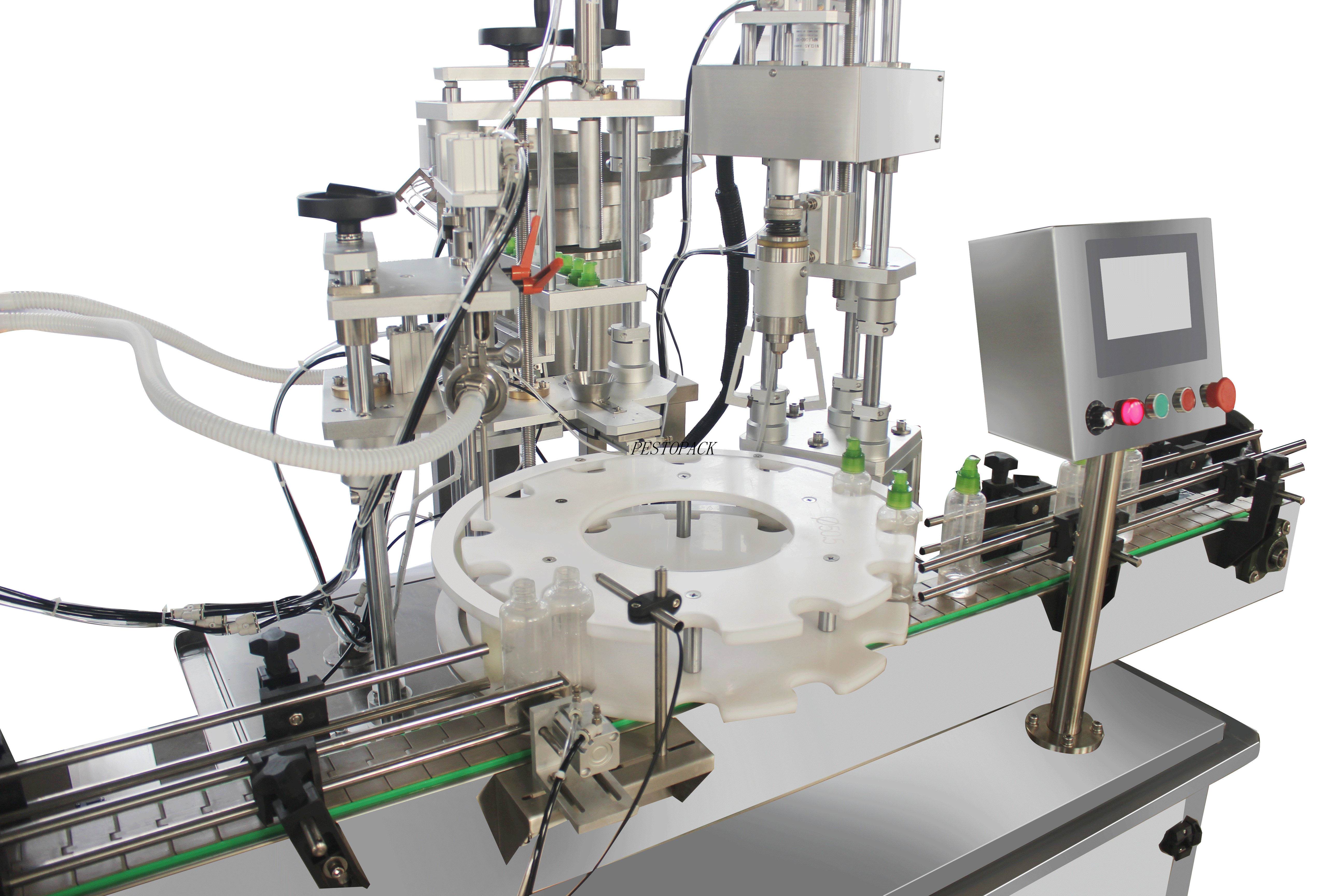

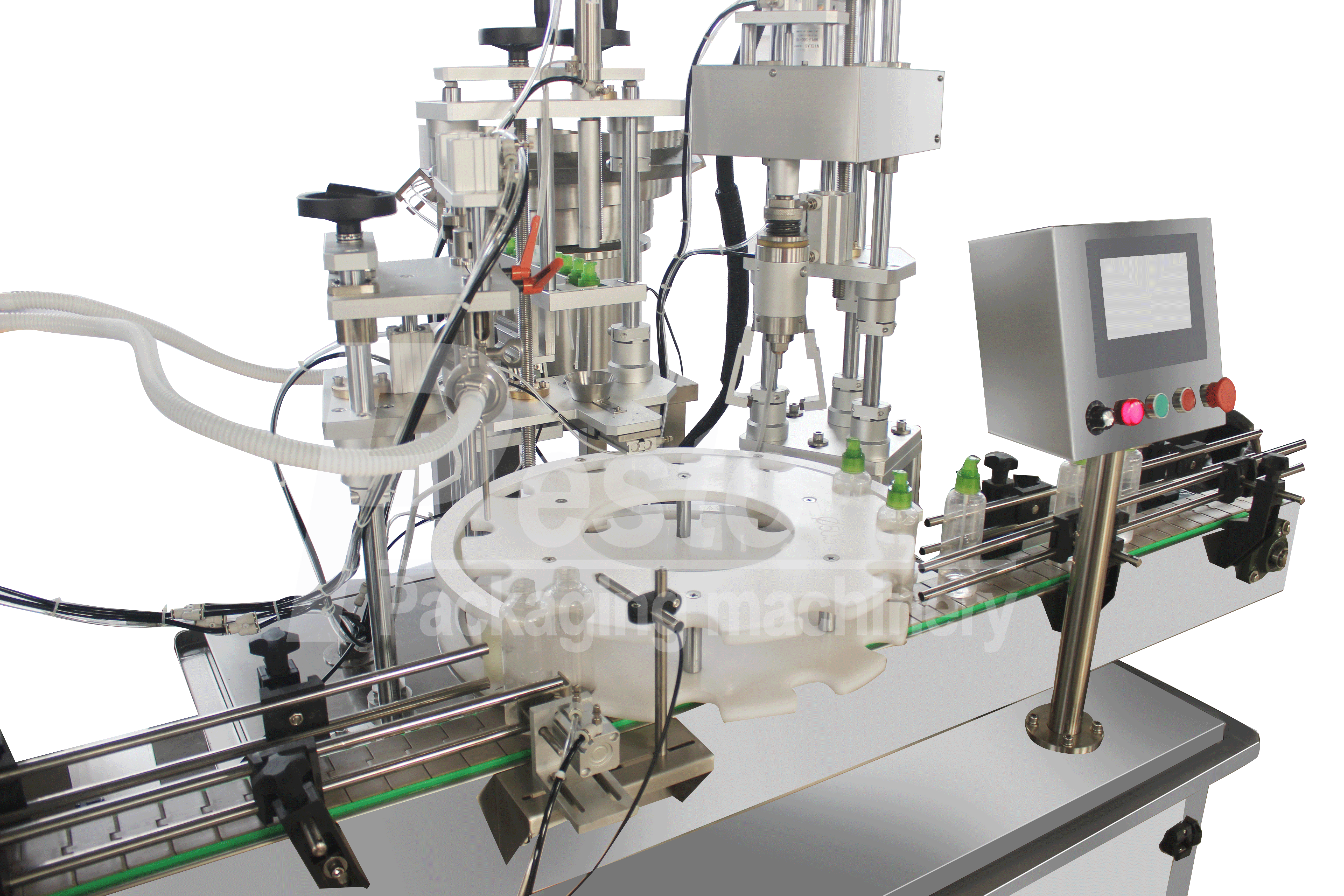

Compact Design

Our machine is designed with a small footprint to save factory space. Even small production facilities can integrate it without major modifications.

Dual Functionality

The 2-in-1 filler and capper reduces the need for separate machines. This dual functionality lowers investment costs and simplifies production management.

Adjustable Filling Parameters

Our detergent filling machine allows for precise adjustment of filling parameters, such as filling volume, speed, and accuracy. This flexibility ensures that your liquid soap product can be filled accurately and efficiently, regardless of its viscosity or packaging size.

Customization Options

Our engineers design machines according to your needs:

Advanced Controls & Automation

PLC and touchscreen operation for ease of use

Stable running with premium electronic components

Fully automated process reduces labor costs

Details Of Hand Sanitizer Filling Machine

1. SUS304 stainless steel for the hand sanitizer filling machine, SUS316 stainless steel is option for contacting product parts.

2. PLC control and touch screen operation for the hand sanitizer filler and capper.

3. High quality electronic components for stable running.

4. Customized design available for multi purpose bottles.

5. Customized design available for pump, spray and trigger caps.

Technical Specifications of Hand Sanitizer Filling Machine

Specification | Details |

Machine Dimension | 1800(L) × 1800(W) × 2100(H) mm |

Bottle Volume | 10–500 ml (customizable) |

Power Supply | AC 380/220V, 50/60 Hz |

Installed Power | 2.5 kW |

Air Pressure | 0.6 Mpa |

Production Capacity | ≤ 1500 bottles per hour (BPH) |

Benefits of Our Hand Sanitizer Filling Machine

1. Hygiene and Safety

2. Flexibility in Packaging

Supports 10 ml travel-size bottles up to 500 ml household bottles

Adapts to different cap types: pump, spray, or trigger

3. Efficiency

4. Cost-Effectiveness

Integrate A Complete Hand Sanitizer Filling Line

We offer comprehensive support in helping our customers integrate a complete hand sanitizer filling line.

Consultation and Analysis

Begin by engaging in detailed discussions with the customer to understand their specific needs and requirements. Determine the desired production capacity, bottle sizes and shapes, types of caps, labeling requirements, and any unique quality control measures they may require.

Customized Solution

Based on the gathered information, we develop a customized hand satinizer filling solution tailored to the customer's requirements. This includes selecting the appropriate liquid detergent filling machine, as well as other packing machines such as conveyors, capping machines, labeling machines, and packaging systems.

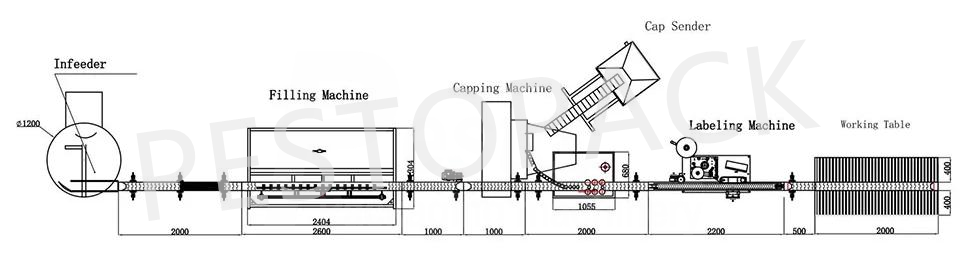

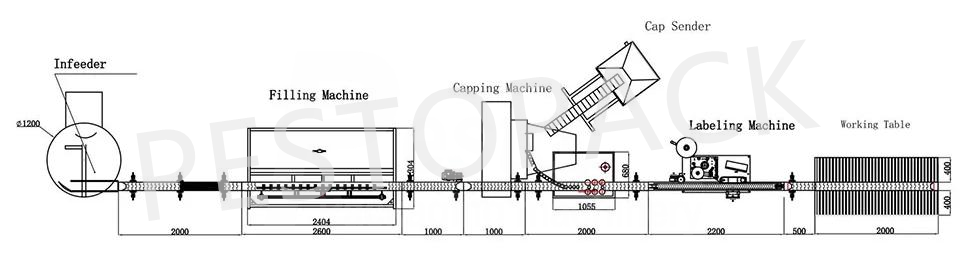

Layout Design

Determine the placement of the different components such as the hand sanitizer filling machine, capping machine, conveyor systems, labeling machine, and quality control stations. Optimize the flow of bottles throughout the hand sanitizer filling line to ensure smooth and efficient production.

Equipment Integration

Our experienced technicians handle the installation and integration of the equipment into the customer's facility. We ensure that all components of the hand sanitizer filling line are properly connected, calibrated, and synchronized for smooth operation.

Procurement and Installation

Procure the selected equipment and install it according to the designed layout. Set up the conveyor systems, connect the hand sanitizer filling system, and ensure they are properly calibrated for accurate filling and capping. Install any required utilities such as electricity, compressed air, ensuring they meet the equipment's specifications.

Testing and Commissioning

Perform comprehensive testing and commissioning of the hand sanitizer filling line. Test the equipment to ensure proper functioning, accuracy, and reliability. Conduct trial runs to verify the production capacity and validate the quality of filled bottles. Make any necessary adjustments or fine-tuning to optimize the line's performance.

Continuous Support

Maintain a strong relationship with the customer by offering ongoing support and assistance. Monitor the performance of the hand sanitizer filling system, gather feedback, and identify areas for improvement. Suggest enhancements to optimize efficiency, reduce waste, and increase productivity.

Comparison: Semi-Automatic vs Automatic Filling Machines

Feature | Semi-Automatic Machine | Automatic Machine |

Production Speed | 200–600 BPH | Up to 1500 BPH |

Labor Requirement | 2–3 operators | 1 operator |

Precision | Medium | High |

Investment Cost | Lower | Higher, but ROI is faster |

Best For | Start-ups, small scale | Medium to large factories |

Future Trends in Hand Sanitizer Production

Eco-friendly packaging (recyclable PET & HDPE bottles)

Automation & robotics to reduce manual handling

Integration with smart monitoring systems (SCADA, IoT)

Flexible filling solutions to meet changing consumer packaging demands

Frequently Asked Questions (FAQs)

Q1: Can the machine handle both gel and liquid sanitizers?

Yes, our machine can be adjusted to handle both low and medium viscosity products.

Q2: What cap types are supported?

Pump, spray, and trigger caps are all compatible with our filling line.

Q3: How fast can it fill bottles?

The machine achieves up to 1500 bottles per hour, depending on bottle size and sanitizer viscosity.

Q4: Is customization possible?

Yes, we provide fully tailored designs for bottle size, labeling, and packaging needs.

Q5: What after-sales services do you provide?

Installation, training, spare parts supply, and ongoing technical support.

Conclusion

PESTOPACK's hand sanitizer filling machine offers a compact, efficient, and customizable solution for manufacturers seeking accuracy, speed, and compliance with international standards. From 10 ml bottles to 500 ml packaging, our machine adapts to your product needs, ensuring high-quality and consistent production output.

Whether you need a standalone machine or a complete turnkey hand sanitizer production line, our team provides consultation, design, installation, and continuous support.

English

العربية

Français

Русский

Español

Português

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

қазақ

हिन्दी

فارسی

Kiswahili

українська

Հայերեն

עברית

বাংলা

සිංහල

Oʻzbekcha

Azərbaycan dili

Български

ქართული

guarani

ગુજરાતી

Hausa

Igbo

ಕನ್ನಡ

Kinyarwanda

Kurdî

Кыргызча

Oluganda

മലയാളം

मराठी

Afaan Oromoo

ਪੰਜਾਬੀ

Runasimi

chiShona

Soomaali

Тоҷикӣ

తెలుగు

ትግንያውያን

Türkmençe

Yorùbá

isiZulu