DISHWASHING LIQUID FILLING MACHINE APPLICATION

Dishwashing liquid is a practical cleaning agent that effortlessly cleans dishes, leaving them clean, hygienic, and shiny. It is widely used in households, the food service industry, and other settings that require dish cleaning. Dishwashing liquid typically falls within a moderate to high viscosity range to ensure it stays on the surfaces of utensils and kitchenware for an adequate period and provides effective cleaning. Viscosity range generally ranges from 1000 to 5000 cps (centipoise).

Matching the viscosity of the detergent with the appropriate detergent filling machine is essential for efficient and accurate production. It ensures that the detergent is dispensed smoothly into the bottles, minimizing wastage and maintaining product quality.

HOW DISHWASHING LIQUID FILLING MACHINE WORKS

The piston filling principle is a common method used in dishwashing liquid filling machine to accurately dispense a predetermined volume of liquid into containers. The filling process begins with the downward movement of the piston. As the piston moves down, it creates a vacuum within the cylinder, drawing the dishwashing liquid into the cylinder through an inlet valve. The dishwashing detergent filling machine is equipped with mechanisms to control the volume of liquid dispensed. This can be achieved by adjusting the stroke length of the piston to the desired fill volume. The volume control ensures accurate and consistent fill levels in each container. The piston filling principle provides precise control over the volume of dishwashing liquid dispensed into each container. It ensures accuracy, minimizes product waste, and maintains consistency in fill levels.

DETAILS OF DISHWASHING LIQUID FILLING MACHINE

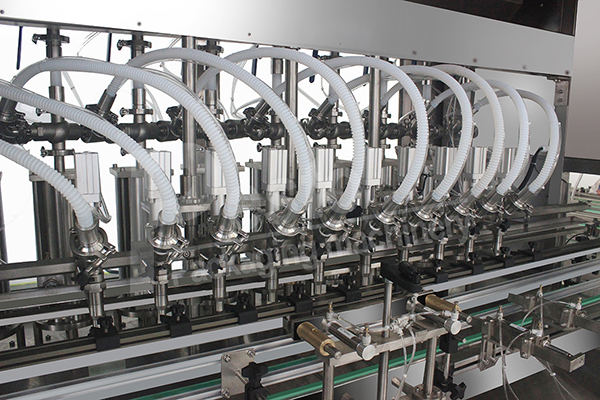

Filling Nozzles

The dishwashing soap filling machine is equipped with high quality filling nozzles that are positioned above the containers. The number and arrangement of the nozzles depend on capacity. The nozzles are designed to fit the container openings and can be adjustable to accommodate different container sizes and shapes.

Measurement System

A measurement system is integrated into the filling machine to accurately measure the volume of dishwashing liquid being dispensed. This can include sensors and piston cylinder that monitor the liquid flow and provide feedback on the amount of liquid being dispensed. The measurement system ensures precise fill volumes and helps maintain consistency.

Control Panel

The dishwashing liquid filling system features a control panel that allows the operator to set parameters, adjust settings, and monitor the filling process. The control panel may include a user-friendly interface, buttons, and digital displays for easy operation and monitoring of the machine's functions.

Safety Features

Dishwashing liquid filling equipment is equipped with safety features to protect operators and prevent accidents. These features can include emergency stop buttons, safety guards, and interlocking mechanisms to ensure safe operation.

Cleaning

There has automated cleaning cycles to facilitate cleaning of the equipment. All pipes and connectors are easy to disassembly.

TECHNICAL PARAMETERS

| Type | Head | Suitable bottles | Speed | Precise | Machine Size | Power | Power Supply | Air |

| PT-Z-20S | 20 |

Customized | 500ml≤5000BPH | ≤0.1% | 2800*1300*2350 | 3.5KW | AC 220/380V;50/60HZ (Customize) | 0.6-0.8Mpa |

| PT-Z-16S | 16 | 500ml≤4000BPH | 2800*1300*2350 | 3.5KW |

| PT-Z-12S | 12 | 500ml≤3000BPH | 2400*1300*2350 | 3KW |

| PT-Z-8S | 8 | 500ml≤2500BPH | 2000*1300*2350 | 3KW |

| PT-Z-6S | 6 | 500ml≤1600BPH | 2000*1300*2350 | 3KW

|

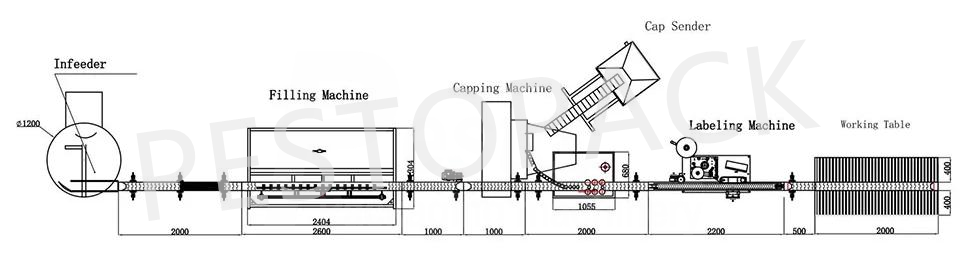

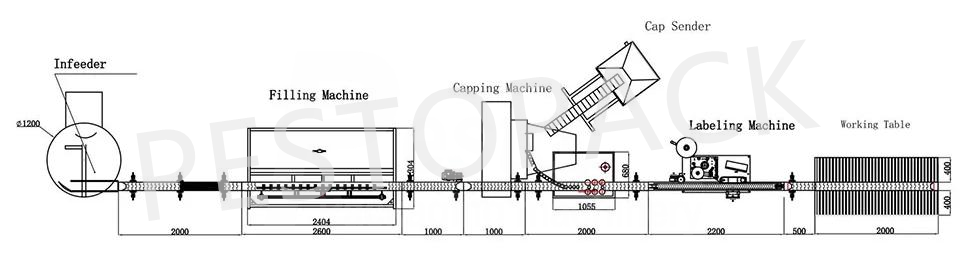

INTEGRATE A COMPLETE DISHWASHING LIQUID FILLING LINE

With our expertise and experience in the field, we can efficiently bring together all the necessary components and equipment to create a fully functional and optimized dishwashing liquid filling system. From the initial design and selection of liquid detergent filling machine to the integration of conveyors, controls, and other supporting elements, we ensure a smooth and efficient process from start to finish. Our goal is to provide a comprehensive solution that meets your specific detergent filling needs, streamlines your production line, and maximizes productivity. Trust our team to deliver a complete dishwashing liquid filling line that meets your requirements and exceeds your expectations. Besides dishwashing liquid filling machines selection, we also should consider capping machines and labeling machines.

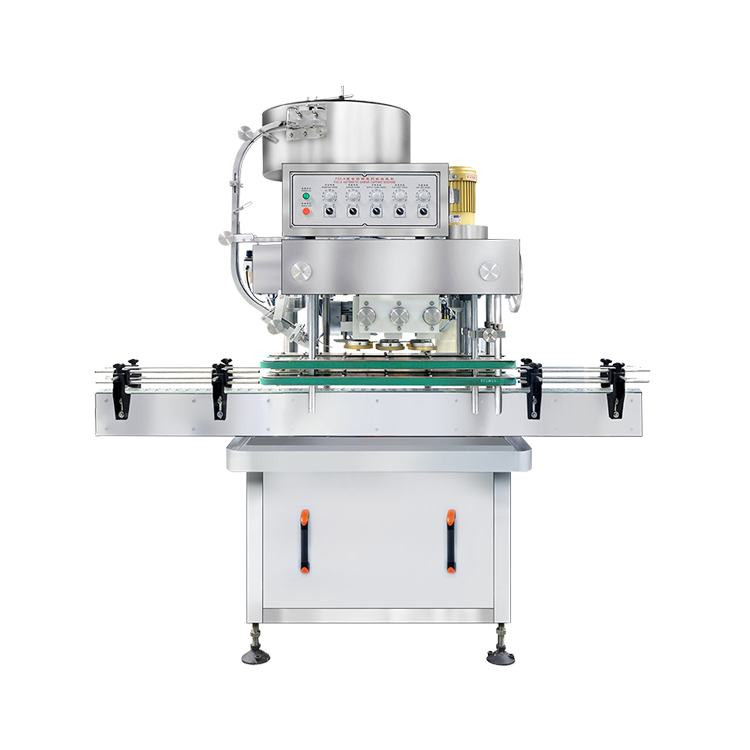

Dishwashing Liquid Capping machine Selection

Dishwashing Liquid Labeling Machine Selection

English

العربية

Français

Русский

Español

Português

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

қазақ

हिन्दी

فارسی

Kiswahili

українська

Հայերեն

עברית

বাংলা

සිංහල

Oʻzbekcha

Azərbaycan dili

Български

ქართული

guarani

ગુજરાતી

Hausa

Igbo

ಕನ್ನಡ

Kinyarwanda

Kurdî

Кыргызча

Oluganda

മലയാളം

मराठी

Afaan Oromoo

ਪੰਜਾਬੀ

Runasimi

chiShona

Soomaali

Тоҷикӣ

తెలుగు

ትግንያውያን

Türkmençe

Yorùbá

isiZulu