What is a gel filling machine?

A gel filling machine is a specialized equipment designed to accurately and efficiently fill gel-based products into various containers, such as jars, bottles, and tubes. It ensures consistent and precise dosing of gel formulations for industries like cosmetics, pharmaceuticals, and personal care.

What types of gel-based products can a gel filling machine handle?

Gel filling machines can handle a wide range of gel-based products, including cosmetic gels, pharmaceutical gels, personal care products, hand sanitizers, lotions, creams, and more.

What are the benefits of using a gel filling machine?

Benefits include increased production efficiency, accurate and consistent fill volumes, reduced material wastage, improved product quality, hygienic filling processes, and the ability to handle a variety of container sizes and shapes.

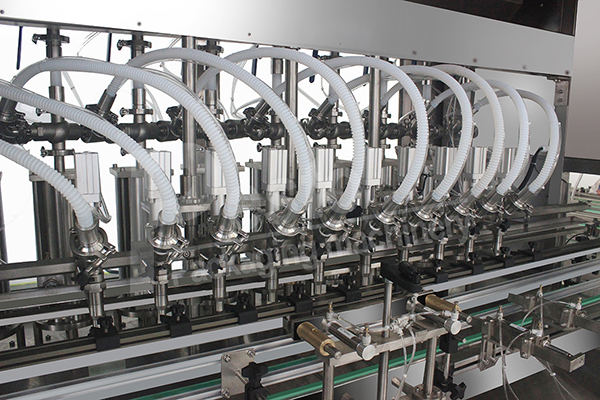

How do gel filling machines work?

Gel filling machines utilize various mechanisms, such as piston pumps, to draw gel from a reservoir and deposit it into containers. The machine's settings allow operators to adjust filling volume, speed, and other parameters.

Are gel filling machines customizable?

Yes, we offer customization options to match specific requirements, such as viscosity, container size, and production speed.

What is the difference between manual, semi-automatic, and fully automatic gel filling machines?

Manual: Requires human intervention for each filling cycle.

Semi-automatic: Operators load containers and initiate the filling process, but the machine handles the actual filling.

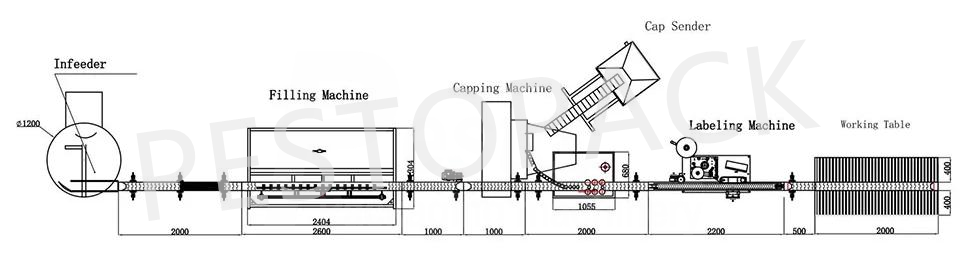

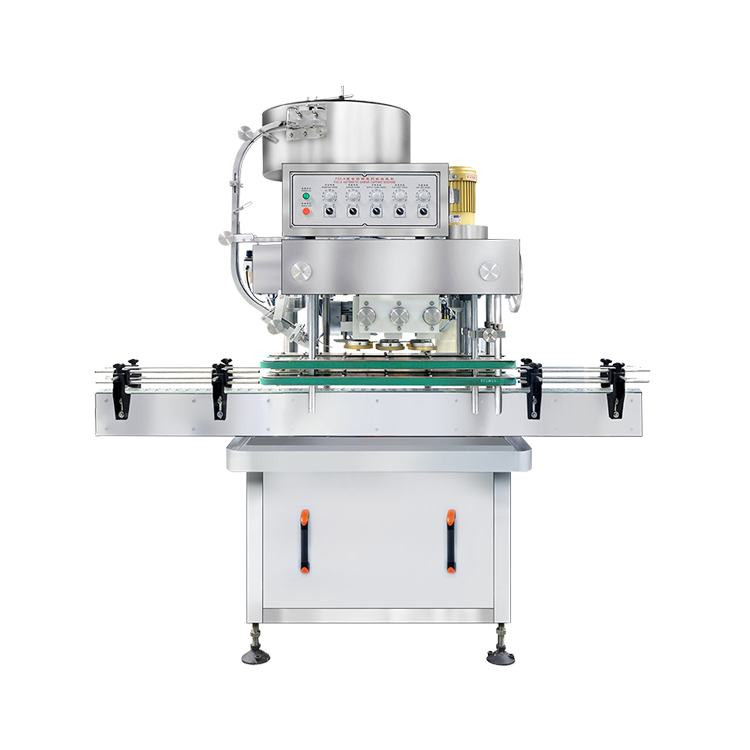

Fully automatic: The machine handles the entire filling process, from container loading to product dispensing and capping.

English

العربية

Français

Русский

Español

Português

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

қазақ

हिन्दी

فارسی

Kiswahili

українська

Հայերեն

עברית

বাংলা

සිංහල

Oʻzbekcha

Azərbaycan dili

Български

ქართული

guarani

ગુજરાતી

Hausa

Igbo

ಕನ್ನಡ

Kinyarwanda

Kurdî

Кыргызча

Oluganda

മലയാളം

मराठी

Afaan Oromoo

ਪੰਜਾਬੀ

Runasimi

chiShona

Soomaali

Тоҷикӣ

తెలుగు

ትግንያውያን

Türkmençe

Yorùbá

isiZulu