LIQUID SOAP FILLING MACHINE APPLICATION

A liquid soap filling machine is designed to handle different viscosities of liquid soap products, from thin handwash formulations to thick dishwashing gels. Using the right filling equipment ensures smooth production, reduced wastage, and high product consistency.

Liquid Soap Filling Machine Application

What Is Liquid Soap?

Liquid soap is a soap formulation in liquid form, commonly used for cleaning hands, dishes, and surfaces.

Low Viscosity Liquid Soaps

Viscosity: 100–500 cP (0.1–0.5 mPa·s)

Thin consistency, flows easily.

Ideal for handwashing and light cleaning tasks.

Medium Viscosity Liquid Soaps

Viscosity: 500–2,000 cP (0.5–2 mPa·s)

Thicker consistency, better coverage.

Suitable for general cleaning and removing dirt and grime.

High Viscosity Liquid Soaps

Viscosity: 2,000–10,000 cP (2–10 mPa·s) or more.

Thick, clingy texture for heavy-duty cleaning.

Common in dishwashing liquids or stain-removal soaps.

Matching the viscosity with the right detergent filling machine is essential for efficiency and quality.

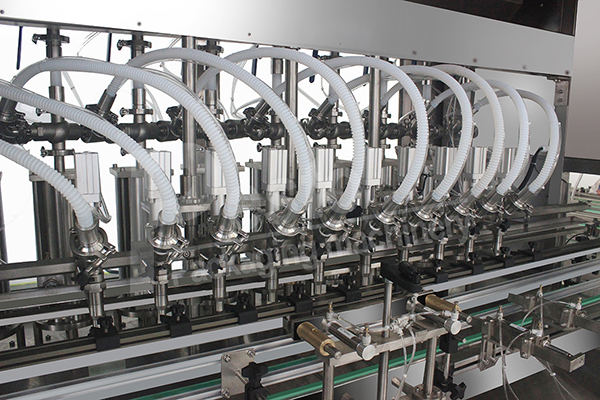

HOW OUR LIQUID SOAP FILLING MACHINE FIT YOUR PRODUCTS

Our liquid soap filling machine and gel filling machine are versatile and adaptable, capable of accommodating a wide range of liquid soap products. Its anti-foam, adjustable parameters, viscosity control, customizable nozzles, easy maintenance, and advanced controls make it an ideal solution for efficiently filling your specific liquid soap product.

Anti-Foam Design

We use a bottom-up filling method and optimized nozzle design to reduce bubbles during filling.

Adjustable Filling Parameters

Easily set filling volume, speed, and accuracy, making it adaptable to different bottle sizes and viscosities.

Viscosity Control

Handles both low and high viscosity liquids without spills or excessive foaming.

Customizable Nozzles

Interchangeable nozzles optimized for different container types and liquid properties.

Easy Cleaning & Maintenance

Quick disassembly for cleaning, ensuring hygiene and preventing cross-contamination.

Advanced Controls & Automation

PLC touchscreen with automated control ensures precision, efficiency, and reduced wastage.

DETAILS OF LIQUID SOAP FILLING MACHINE

Technical Parameters of Liquid Soap Filling Machines

Model | Heads | Suitable Bottles | Speed (500ml) | Precision | Machine Size (mm) | Power | Supply | Air Pressure |

PT-Z-20S | 20 | Customized | ≤5000 BPH | ≤0.1% | 2800×1300×2350 | 3.5KW | AC 220/380V; 50/60HZ | 0.6–0.8Mpa |

PT-Z-16S | 16 | 500ml | ≤4000 BPH | ≤0.1% | 2800×1300×2350 | 3.5KW | AC 220/380V; 50/60HZ | 0.6–0.8Mpa |

PT-Z-12S | 12 | 500ml | ≤3000 BPH | ≤0.1% | 2400×1300×2350 | 3KW | AC 220/380V; 50/60HZ | 0.6–0.8Mpa |

PT-Z-8S | 8 | 500ml | ≤2500 BPH | ≤0.1% | 2000×1300×2350 | 3KW | AC 220/380V; 50/60HZ | 0.6–0.8Mpa |

PT-Z-6S | 6 | 500ml | ≤1600 BPH | ≤0.1% | 2000×1300×2350 | 3KW | AC 220/380V; 50/60HZ | 0.6–0.8Mpa |

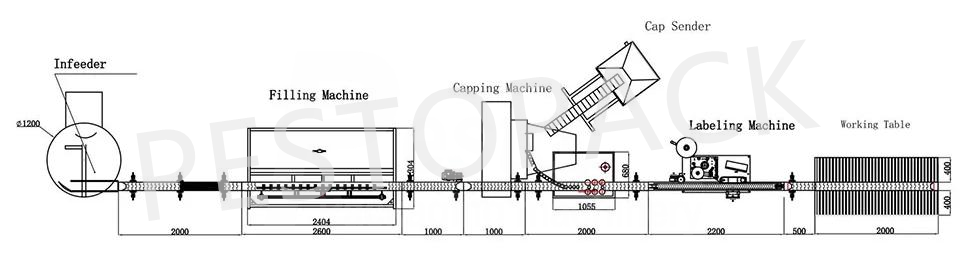

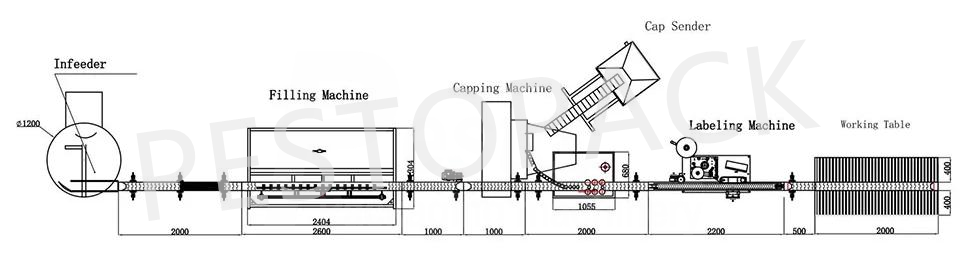

INTEGRATE A COMPLETE LIQUID SOAP FILLING LINE

We offer comprehensive support in helping our customers integrate a complete liquid soap filling line.

Consultation and Analysis

Our team of experts starts by understanding the specific requirements of the customer's production needs. We conduct a thorough consultation to gather information about production volumes, container types, desired automation level, and any special considerations.

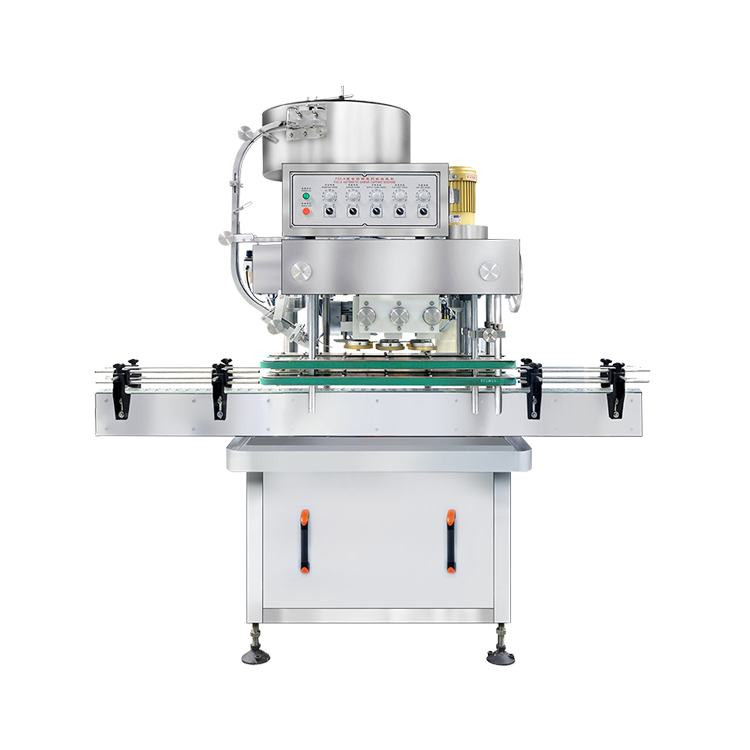

Customized Solution

Based on the gathered information, we develop a customized solution tailored to the customer's requirements. This includes selecting the appropriate liquid detergent filling machine, as well as other equipment such as conveyors, capping machines, labeling machines, and packaging systems.

Layout Design

We assist in designing the layout of the complete liquid soap filling line, considering factors such as space availability, workflow efficiency, and ergonomic considerations. This ensures a seamless flow of production and optimal utilization of resources.

Equipment Integration

Our experienced technicians handle the installation and integration of the equipment into the customer's facility. We ensure that all components of the liquid soap filling line are properly connected, calibrated, and synchronized for smooth operation.

Testing and Training

Once the installation is complete, we conduct rigorous testing to ensure that the liquid soap filling line functions accurately and efficiently. We also provide comprehensive training to the customer's operators on the operation, maintenance, and troubleshooting of the equipment.

Ongoing Support

Our support doesn't end with installation and training. We offer ongoing technical support, preventive maintenance services, and spare parts supply to ensure the continuous and reliable operation of the liquid soap filling line.

Liquid Soap Capping machine Selection

Liquid Soap Labeling Machine Selection

English

العربية

Français

Русский

Español

Português

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

қазақ

हिन्दी

فارسی

Kiswahili

українська

Հայերեն

עברית

বাংলা

සිංහල

Oʻzbekcha

Azərbaycan dili

Български

ქართული

guarani

ગુજરાતી

Hausa

Igbo

ಕನ್ನಡ

Kinyarwanda

Kurdî

Кыргызча

Oluganda

മലയാളം

मराठी

Afaan Oromoo

ਪੰਜਾਬੀ

Runasimi

chiShona

Soomaali

Тоҷикӣ

తెలుగు

ትግንያውያን

Türkmençe

Yorùbá

isiZulu