What Are Jar Filling Machines?

Jar filling machines are automated systems that dispense liquids, creams, powders, or granules into jars with precision. They reduce manual labor, increase production efficiency, and guarantee consistency.

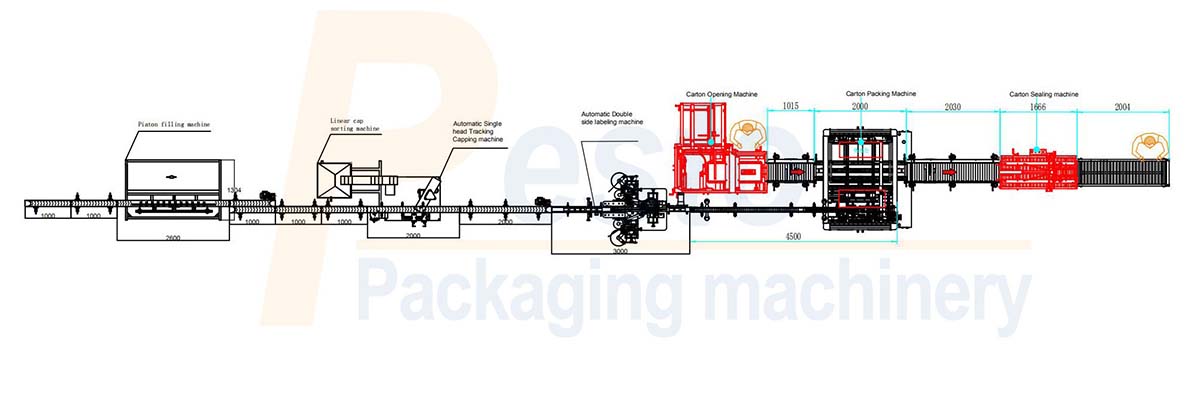

Whether you require a small jar filling machine for a startup or a fully automated jar filling line for industrial-scale production, Pestopack offers tailored solutions that match your product type, jar material, and output needs.

Glass Jar Filling Machines

Glass jars are commonly used for premium products due to their durability, chemical resistance, and ability to preserve freshness. However, they are fragile, which requires specialized handling.

Features of Glass Jar Filling Machines:

Gentle jar handling to prevent breakage

Compatibility with jars of different shapes and sizes

Hygienic design for food and pharmaceutical applications

Industries & Applications:

Food & Beverage: jams, sauces, spices, honey

Cosmetics: creams, scrubs, masks

-

Pharmaceuticals: ointments, medicinal pastes, syrups

Plastic Jar Filling Machines

Plastic jars are lightweight, cost-effective, and widely used in consumer packaging. They are especially popular for household chemicals, personal care products, and large-volume food packaging.

Advantages of Plastic Jar Filling Equipment:

High-speed filling capability

Flexible for multiple plastic materials (PET, PP, HDPE)

Lower shipping costs compared to glass jars

Applications:

Food Products: sauces, condiments, peanut butter

Household Chemicals: detergents, cleaning agents

-

Personal Care: lotions, creams, gels

Applications of Jar Filling Machines

Pestopack designs jar filling machines for specific product characteristics to maintain quality and efficiency.

Honey Jar Filling Machine

HONEY FILLING MACHINE

PESTOPACK offers a range of honey filling machines, capping machines, labelling machines, conveyor belts . Our automatic honey filling machine can handle unique honey packaging designs with consistent accuracy and speed throughout the filling process. After installing our honey bottle filling machine in your facility, efficiency and productivity will be increased.

Sauce Jar Filling Machine

Adjustable settings for different sauce consistencies

Prevents spillage and maintains product integrity

Suitable for ketchup, chili sauce, mayonnaise, and salad dre

SAUCE FILLING MACHINE

Automatic sauce filling machines are a kind of full automatic filling machines specially developed by our company for various sauces. Our sauce filling machines are equipped with advanced technology for precise filling, ensuring every bottle is consistently filled to perfection.

Jam Jar Filling Machine

Handles thick fruit preserves with chunks

Equipped with PLC and touchscreen controls for precision

Meets GMP standards for food safety

JAM FILLING MACHINE

Jam filling machine has reached the international advanced level ,partial has exceeded the similar product. It is also suitable for the filling of daily chemicals,oil liquid,sauce,getergent liquid,cosmetics,medicinel liquid and flammable and explosive liquid . It adopts PLC and touch screen control panel for control material.Jam filling machine is characterized by accurate measuring ,advanced structure ,stable operating ,low noise ,large adjusting range ,fast filling speed. Operators adjust and meter figure in the touch screen control panel , also can adjust metering of each filling head. The external surface of this ketchup filling machine is made of excellent stainless steel . Good appearance , applied to GMP standard. This jam filler can applicable to fruit jams like apple jam, orange jam, blueberry jam, strawberry jam and chilli sauce products.

Cosmetic Cream Jar Filling Machine

Advanced piston technology for thick creams and lotions

Reduces wastage with accurate dispensing

Ideal for skincare, haircare, and pharmaceutical creams

CREAM FILLING MACHINE

Our cream filling machine for cosmetic is equipped with advanced piston filling technology. It ensures precise and consistent filling with minimal human intervention, reducing the chances of errors and product wastage. It's designed to handle a wide range of products, making it an ideal choice for various industries, including cosmetics, food, and pharmaceuticals. From thick creams to liquid lotions, it can efficiently fill them all.

TYPES OF JAR FILLING MACHINES

Gravity Jar Filling Machines

Perfect for thin to semi-viscous liquids, gravity fillers rely on gravity to dispense products, offering accuracy and efficiency in filling operations.

These machines operate on a fundamental principle—utilizing gravity to dispense products into containers with remarkable accuracy and consistency.

The design simplicity of gravity fillers contributes to their reliability. They work by relying on the force of gravity to naturally fill containers from an elevated reservoir, ensuring a smooth and controlled flow of liquids into the jars. This method is particularly effective for products with low to moderate viscosity, including water, juices, oils, and more.

One of the standout features of gravity fillers is their adaptability to various container sizes and shapes. Their versatility allows seamless integration into different production lines, offering precision filling while maintaining a high level of efficiency.

Our gravity jar filling machines are engineered to deliver consistent, accurate fills, meeting the demands of industries where precise liquid filling is essential. Their intuitive operation and dependable performance make them an invaluable asset for your production needs.

GRAVITY FILLING MACHINE

Gravity filling machine is a simple and economical solution. . This filling principle operates by storing the liquid above the bottles to be filled and allowing gravity to draw the liquid down. Liquid fillers are for a wide range of low ot thin viscous products. Gravity liquid fillers can be manufactured as automatic filling machines or they can be built to run in a semi-automatic fashion, making the filling machines useful to facilities with almost any level of production.

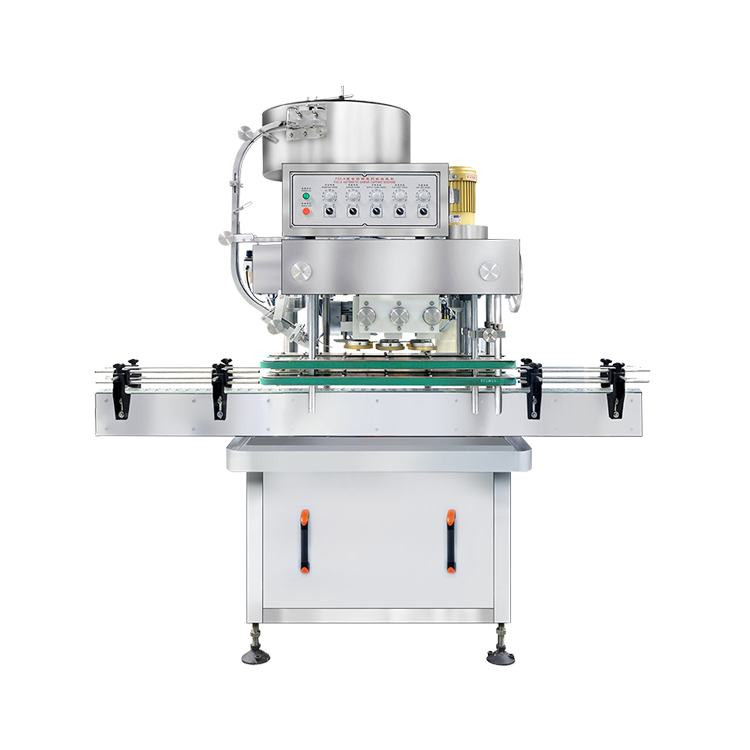

Piston Jar Filling Machines

Tailored for viscous substances like pastes and creams, piston, gel fillers utilize a piston-driven mechanism to ensure accurate fills with controlled viscosity. These machines operate on a sophisticated yet efficient piston-driven mechanism, ensuring precise measurements and controlled fills for a diverse range of products.

The key to the effectiveness of piston fillers lies in their ability to precisely control the volume of product dispensed. As the piston moves within a cylinder, it draws in the substance and then dispenses it into the jars with consistent accuracy. This mechanism allows for fine-tuning and adjustments, accommodating different viscosities and ensuring uniform fills across various jar sizes and shapes.

What sets piston jar filling machines apart is their adaptability to handle a wide spectrum of products, from thick creams and lotions to chunky sauces or dense pastes. This versatility makes them indispensable for industries requiring precise and controlled filling of viscous materials.

Our line of piston jar filling machines is designed to meet the rigorous demands of modern production lines, offering reliability, accuracy, and the capability to handle diverse substances. Their customizable settings and consistent performance make them an essential component in ensuring high-quality fills for your jarred products.

PISTON FILLING MACHINE

Piston filling machines incorporate innovative features to provide maximum speed and optimum filling accuracy. Complete control and ease of use through simple touchscreen operation.Piston filler machines are available in single or multi-head designs and are ideal for automated operations.Our automatic piston filling machine is suitable for various viscous liquids and non-viscous liquids. It is suitable for liquid filling such as water, oil, sauce, daily chemical, pesticide, etc. Widely used in oil products, food, daily chemicals, cosmetics, medicine and other industries.

Rotor Pump Jar Filling Machines

Specifically crafted for various viscosities, rotor pump fillers efficiently dispense a wide range of products, ensuring accuracy and reliability in the filling process.

Rotor pump jar filling machines stand as a pinnacle of versatility and efficiency in handling a vast array of substances across different viscosities. These machines are engineered with a rotor-driven pumping system, designed to precisely dispense a wide spectrum of products into jars with unparalleled accuracy and consistency.

The functionality of rotor pump fillers relies on the rotational motion of a pump rotor. This mechanism allows for controlled filling, ensuring products such as liquids, semi-viscous materials, creams, and even products with particulates or chunks are dispensed evenly and without compromise.

What distinguishes rotor pump fillers is their adaptability. These machines are adept at handling a diverse range of product textures and viscosities, making them an ideal choice for industries where filling various substances into jars is a requirement.

The precision and reliability of our rotor pump jar filling machines make them an invaluable asset to your production line. Their capability to handle a multitude of products efficiently while maintaining accuracy in fills across different container sizes and shapes ensures a seamless and consistent packaging process for your range of jarred goods.

ROTOR PUMP FILLING MACHINE

This rotary pump filling machine is suitable for filling all kinds of high-viscosity materials (viscosity 700-60000cp). Such as various mayonnaise, butter, lotion, salad Dressing, honey, syrup, glue, face cream, facial cleanser, fruit puree, edible oil, etc.. The rotor lobe pump filler has simple structure, convenient operation and cleaning, and the number of filling heads can be determined according to the actual production needs of users.

Overflow Jar Filling Machines

Engineered for liquids, our overflow fillers ensure precise fill levels by allowing excess liquid to flow, preventing spills and maintaining consistency.

Overflow jar filling machines represent precision and reliability in liquid filling. These machines excel in maintaining consistent fill levels, making them ideal for a wide range of liquid products such as sauces, syrups, oils, and more.

The mechanism behind overflow fillers is ingenious; as the product reaches the desired level in the container, any excess liquid spills over into a catchment area, ensuring the exact fill volume without spillage or wastage. This design not only guarantees accurate fills but also maintains the cleanliness of the containers and the surrounding workspace.

With their ability to handle various container sizes and shapes, overflow fillers offer versatility in production lines. Their intuitive operation, coupled with their precision, makes them a vital asset for industries requiring meticulous liquid filling.

Our range of overflow automatic jar filling machines is engineered to meet diverse needs, offering reliability, accuracy, and efficiency, ensuring your liquid products are filled flawlessly every time.

English

العربية

Français

Русский

Español

Português

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

қазақ

हिन्दी

فارسی

Kiswahili

українська

Հայերեն

עברית

বাংলা

සිංහල

Oʻzbekcha

Azərbaycan dili

Български

ქართული

guarani

ગુજરાતી

Hausa

Igbo

ಕನ್ನಡ

Kinyarwanda

Kurdî

Кыргызча

Oluganda

മലയാളം

मराठी

Afaan Oromoo

ਪੰਜਾਬੀ

Runasimi

chiShona

Soomaali

Тоҷикӣ

తెలుగు

ትግንያውያን

Türkmençe

Yorùbá

isiZulu