VIDEO OF EDIBLE OIL FILLING MACHINE

FEATURES OF EDIBLE OIL FILLING MACHINE

Edible oil filling machines and cooking oil filling machines are widely used in the food and beverage industry, particularly in the production of vegetable oil, olive oil, soybean oil, canola oil, and other edible oils. The edible oil packaging machine and vegetable oil filling machine are also commonly used in the pharmaceutical and chemical industries for filling oils, syrups, and other liquid products. Whatever small oil filling machine or large scale oil filling machine, Pestopack provides comprehensive machine and service for you. There are features of edible oil bottling machine:

High accuracy

As one kind of piston filling machine, edible oil filling machines for sale are designed to fill bottles and containers accurately with servo motor controlled pistons, ensuring that the correct amount of oil is dispensed into each container.

Speed

Our oil bottle filling machine and cooking oil filling machine are capable of filling a large number of bottles or containers in a short amount of time, increasing productivity and efficiency.

Varying bottle sizes and shapes

The edible oil filling equipment can be adjusted to accommodate different bottle sizes and shapes, allowing for greater flexibility in production.

Non-drip filling

Filling nozzles are designed to prevent drips, ensuring that the oil is dispensed cleanly and efficiently.

Easy to clean

Oil bottle filling machines are designed to be easy to clean, with minimal parts that need to be disassembled for cleaning.

Hygienic design

Pestopack's automatic edible oil filling machines are designed with hygiene in mind, with features such as stainless steel construction and easy-to-clean surfaces that reduce the risk of contamination.

Automatic control

Our edible oil filling systems are fully automated, with computerized controls that monitor and adjust the filling process, ensuring consistent quality and accuracy.

TECHNICAL PARAMETERS OF EDIBLE OIL FILLING MACHINE

Filling heads | 4 | 6 | 8 | 12 |

Production speed

(bottles/hour) | 1L:1000,5L:800 | 1L:1800,5L:1200 | 1L:2200,5L:1600 | 1L:3500,5L:2800 |

Filling accuracy | 1-5L:±5ml |

Filling range | 500-5000ml |

Suitable bottles | Round barrel:height:100-320mm;diameter:Φ100-180mm

Drum: length:100-200mm;width:40-80mm;height:150-300mm

Neck diameter:≤Φ30mm |

Power | 3KW | 3KW | 4KW | 5KW |

Power source | 220/380V 50/60Hz |

Air source | 0.6Mpa |

Dimension(mm) | 1600×1100×2200 | 2000×1100×2200 | 2400×1100×2200 | 2600×1500×2200 |

DETAILS OF AUTOMATIC OIL BOTTLE FILLING MACHINE

✅ High quality stainless steel frame with mirror finish for edible oil bottle filling machine.

✅ Quick clamps for easy disassembly and cleaning. Meet GMP requirement.

✅ The edible oil bottle filling machine is installed in servo motor. No dropping when filling with high accuracy.

✅ Quantitative filling and easy adjust filling volume in touch screen.

✅ No residual Angle for three-way valve, long service life.

✅ Wiring system in automatic edible oil filling machine is tidy with tag in independent electronic cabinet.

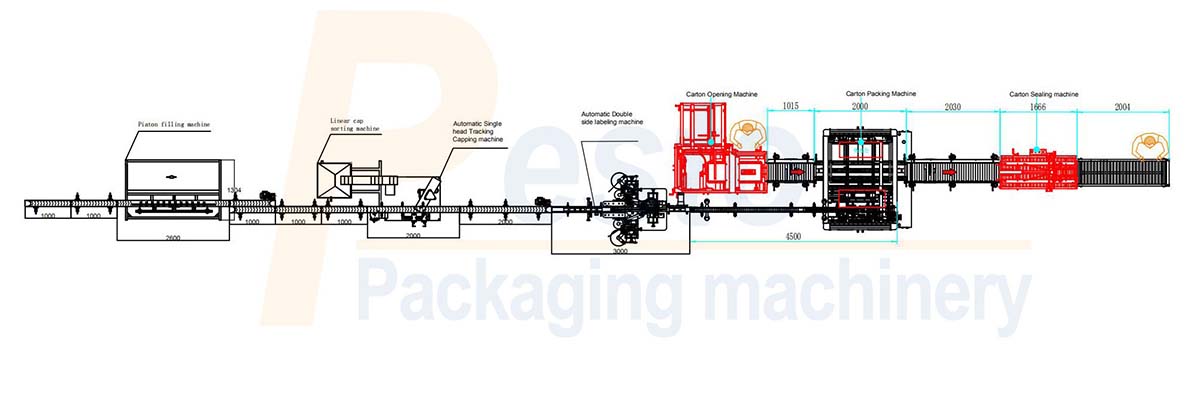

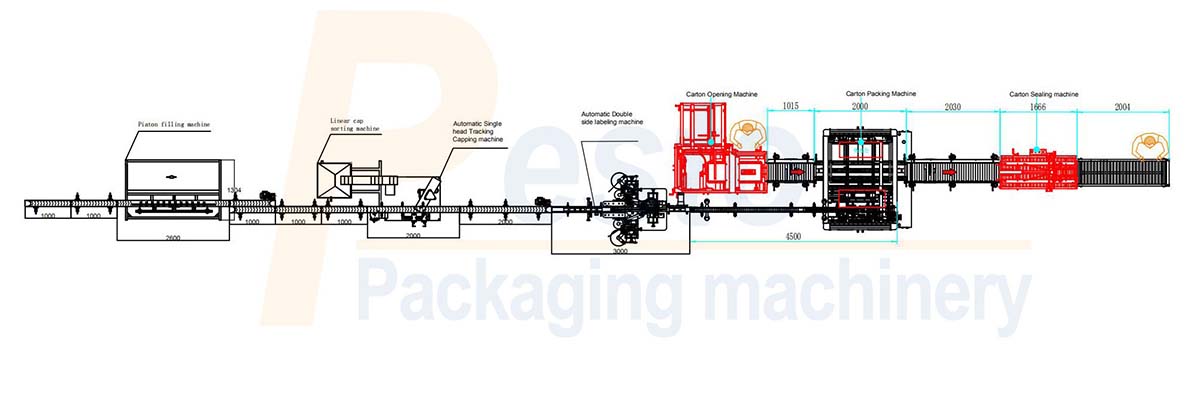

INSTALL A COMPLETE EDIBLE OIL FILLING LINE

As one of leading edible oil filling machine manufacturers in China, we can help you choose oil filling machinery based on the viscosity of your product to improve the efficiency of your production line and increase productivity. Following completion of the oil filling process, cappers can apply different types of caps to packages, forming an airtight and liquid-tight seal that prevents contamination and leakage. Labelers can apply high-quality custom-printed labels to paste jars and other types of containers. A system of conveyors keeps the entire liquid packaging process efficient, carrying containers between stations with consistent efficiency. This combination of equipment can form a edible oil filling line that provides years of reliable operation.

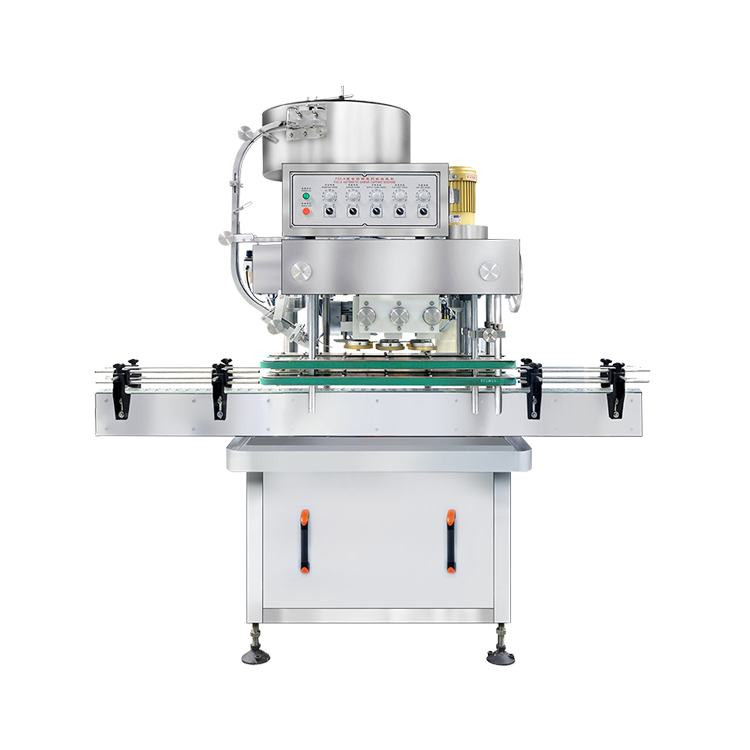

Oil Capping machine Selection

Oil Labeling Machine Selection

BENEFITS OF EDIBLE OIL BOTTLE FILLING MACHINE

WIDE APPLICATIONS

This edible oil filling equipment is mainly for viscous products in food and sauce, skin care, household, chemical industries, like oil, honey, tomato sauce, skin cream, detergent products.

USER-FRIENDLY

Easily controlled by PLC and touch screen operation. Parameter data can be adjusted and saved in touch screen. Only one worker can operation without complex process.

COST-EFFECTIVE

Much higher effective than semi automatic and manual operation with long life. This oil bottle filling machine is an ideal machine for production.

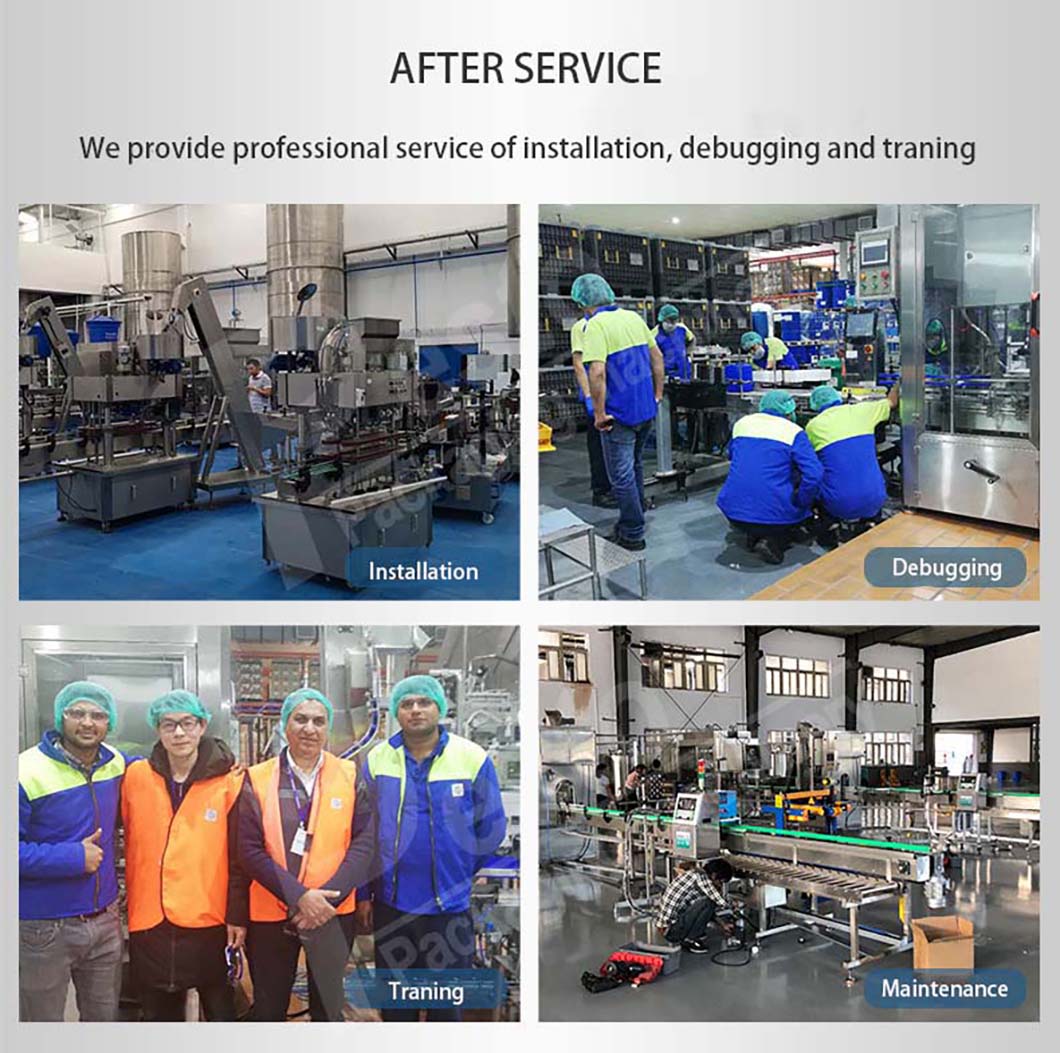

EASY INSTALLATION

Whole oil bottle filling machine will be packed before shipping. Only just connect with conveyor as per layout. We provide complete operation manual, installation video, commissioning video and online technology support to make sure fully understand.

EASY CLEANING

We utilize high-quality stainless steel frames , international famous brand electrical components , the edible oil filling system is applied to GMP standard requirement.All valves and clamps are easy to disassembly to clean.

English

العربية

Français

Русский

Español

Português

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

қазақ

हिन्दी

فارسی

Kiswahili

українська

Հայերեն

עברית

বাংলা

සිංහල

Oʻzbekcha

Azərbaycan dili

Български

ქართული

guarani

ગુજરાતી

Hausa

Igbo

ಕನ್ನಡ

Kinyarwanda

Kurdî

Кыргызча

Oluganda

മലയാളം

मराठी

Afaan Oromoo

ਪੰਜਾਬੀ

Runasimi

chiShona

Soomaali

Тоҷикӣ

తెలుగు

ትግንያውያን

Türkmençe

Yorùbá

isiZulu