Water bottling machines are important for business that produce bottled water. A good quality water bottling machine helps businesses to streamline your production process, reduce cost, and increase profitability. This article guides you step by step on how to choose the right water bottling machine from the type of water bottling machine, production capacity, features, after-sales service, installation and commissioning, safety, price.

1. What are the key features to look for when purchasing a water bottling machine

2. What is production capacity of a water bottling machine

3. What bottle types and sizes can be used with water bottling machines

4. How do water bottling machine fill bottles

5. How reliable and durable is a water bottling machine

6. What is the maintenance and upkeep required for a water bottling machine

7. What is the warranty and after-sales support offered by Pestopack

8. Are there any safety considerations when using a water bottling machine

9. How to ensure the quality of water produced by a water bottling machine

10. How long does it take to set up a water bottling machine

11. How much does a water bottling machine cost

12. Why choose water bottling machine manufacturer Pestopack

What are the key features to look for when purchasing a water bottling machine

When purchasing a water filling machine, some of the key features to consider include:

Production capacity:

This refers to the amount of water the machine can produce within a given time frame. It's essential to choose a waer bottling machine that can meet your production needs.

Quality of material:

The water bottling machine's quality determines how durable it is, how well it can perform over time, and how easy it is to maintain. A machine made from high-quality materials will likely last longer and require less maintenance.

Filtration system:

The filtration system is critical for ensuring that the water produced by the machine is safe and clean to drink. A good water bottling machine should have a robust filtration system that removes impurities and contaminants from the water.

Bottle size and shape:

The machine should be able to accommodate the bottle size and shape you want to use.

Automation of water bottling machine:

Fully automated water bottling machines are easier to use and can reduce the risk of human error during the bottling process. If you're planning on producing large quantities of water, it is worth investing in a fully automated machine.

Maintenance and cleaning:

The water bottling machine should be easy to clean and maintain to ensure that it performs optimally over time.

Cost:

The price of the water bottling machine is an important factor to consider. However, it's essential to balance cost with quality and ensure that you're getting a machine that can meet your production needs and produce high-quality water.

What is production capacity of a water bottling machine

Production capacity of a water bottling machine for sale will depend on several factors, including the speed at which the water bottling machine can fill bottles, the size of the bottles being filled, and the level of automation of the water bottling machine. Water bottling machines for sale with higher levels of automation and faster filling speeds will typically have higher production capacities. Pestopack provides a wide range of water filling machines from 3000-24000BPH, you can select one suitable water bottling machine based on your requirement.

What bottle types and sizes can be used with water bottling machines

Water bottling machines can generally be designed to accommodate a variety of bottle types and sizes, depending on the specific model. Here are some common bottle types and sizes that can be used with water bottling machines:

PET bottle water bottling machine:

PET bottles are the most common type of bottle used for water bottling. They come in various sizes, ranging from small single-serving bottles to large 5-gallon jugs. PET bottles are lightweight, durable, and easy to recycle.

Glass bottle water bottling machine:

Glass bottles are another option for water bottling. They are heavier than PET bottles and may be more expensive, but they are also more environmentally friendly and can provide a premium look and feel to your product. Glass bottles can come in various shapes and sizes.

Pestopack's water bottling machines have different types for different bottle sizes and material. For example, you need different water bottling plant for pet bottle and glass bottle. For portable water, water bottling machine can be used from 200-2000ml. 3L-10L water bottle, will use another type of water bottling machine. And we will use specific water bottling machine for 3-5 gallon water bottle.

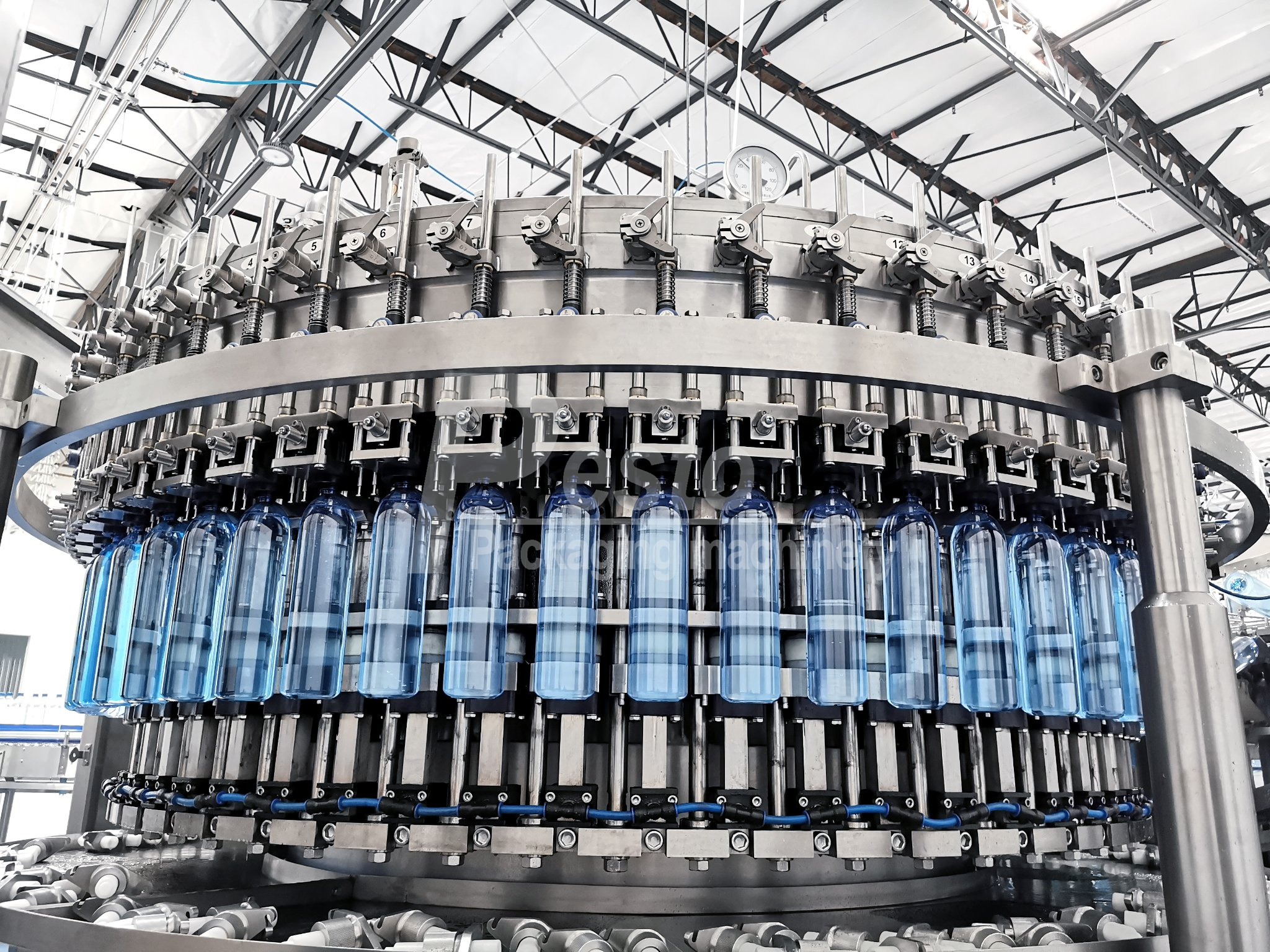

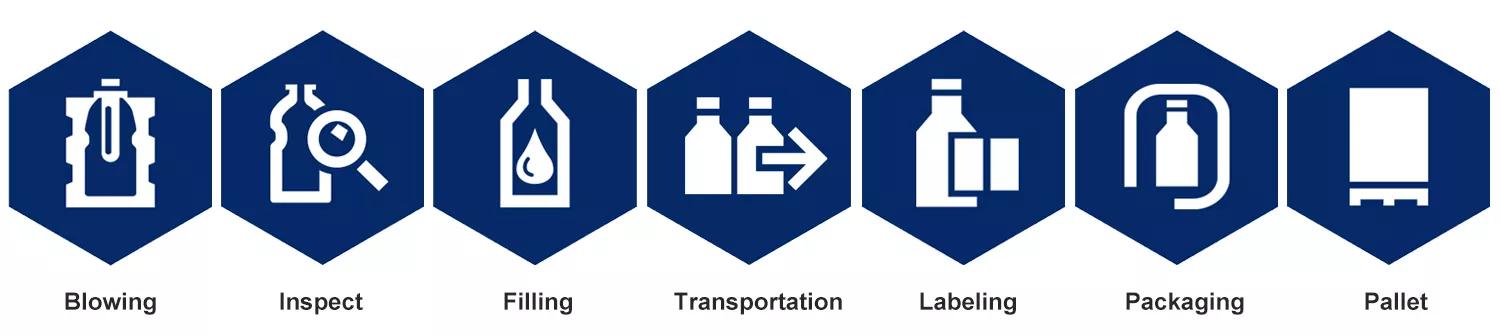

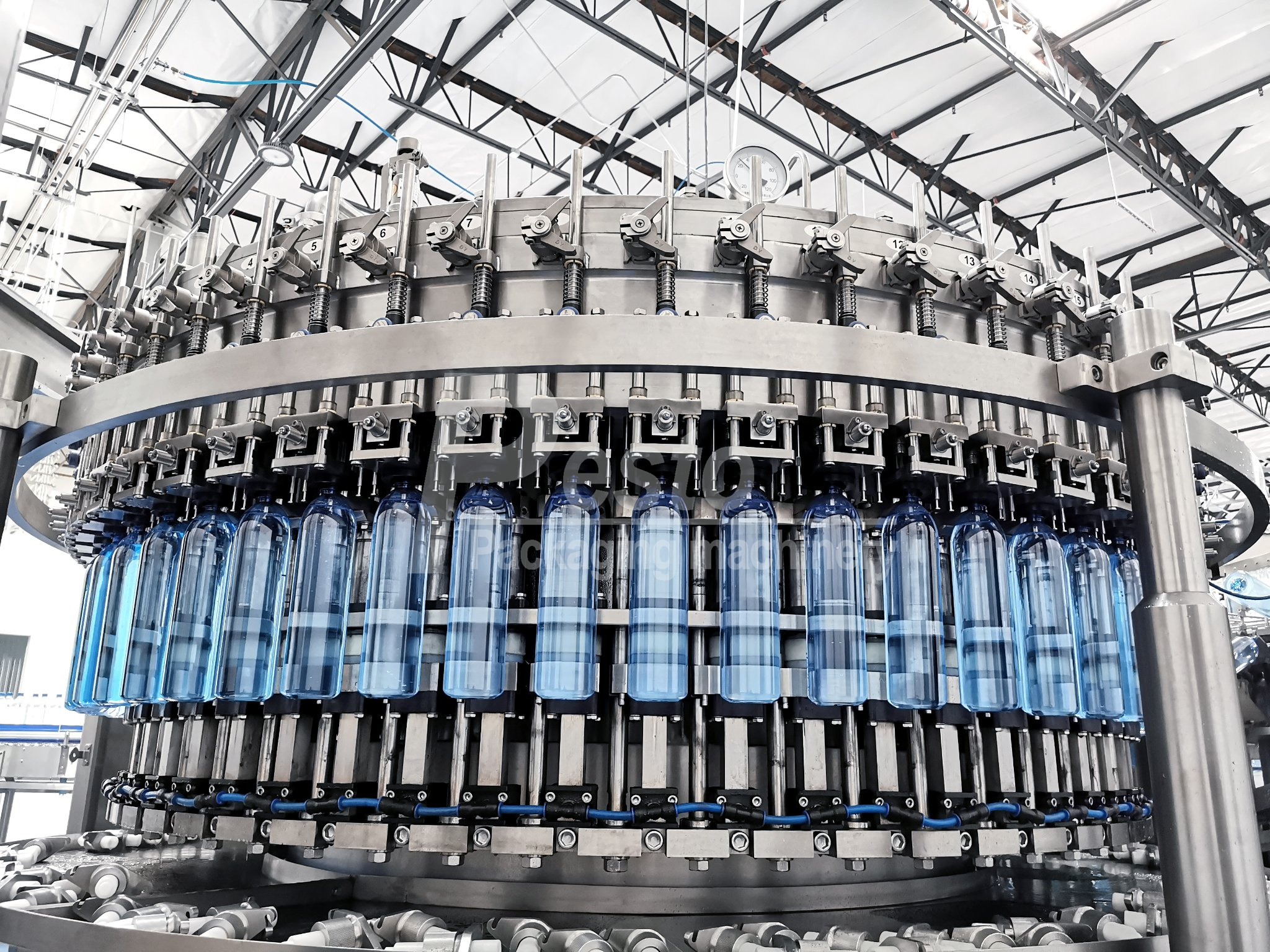

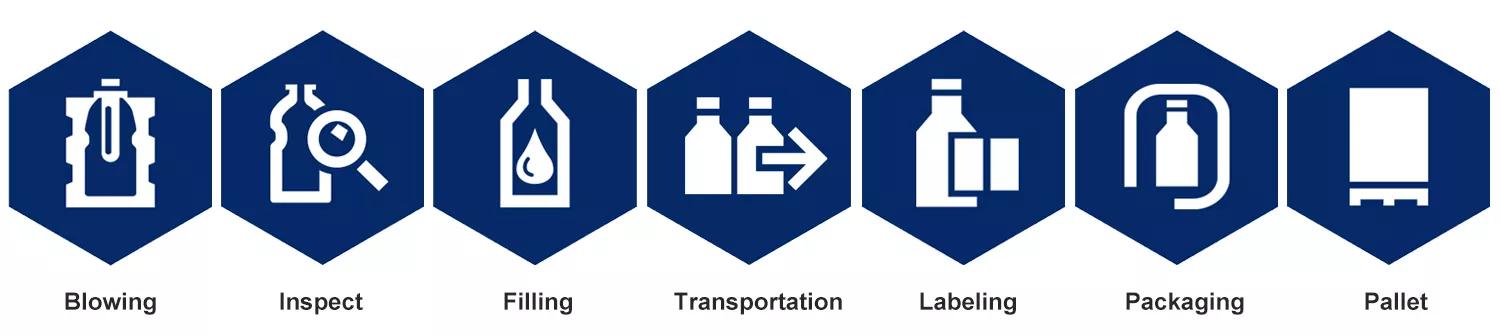

How do water bottling machine fill bottles

Water filling machine for sale fills bottles using a multi-step process. The process includes the following steps:

Blowing:

Bottle preform are loaded to blowing machine that produce empty bottle.

Bottle loading:

The empty bottles are loaded onto a air conveyor that carries them through the filling process.

Washing:

Before filling, the bottles are cleaned and sterilized to ensure they are free from contaminants. And caps also be cleaned by online cap sterilizer.

Filling:

The filling process starts with the bottles being positioned under the filling heads. The machine uses a series of valves, pumps, and sensors to measure and control the flow of water into the bottles. The water is typically sourced from a storage tank or municipal water supply.

Capping:

Once the bottles are filled, they are moved to the capping station. The caps are fed into the machine, and a capping mechanism applies the caps to the bottles.

Labeling:

After capping, the bottles are moved to the labeling station. A label is applied to each bottle, which may include information about the brand, product, and other details.

Packaging:

Finally, the bottles are packaged into film or carton.

How reliable and durable is a water bottling machine

The reliability and durability of a water bottling machine depend on various factors such as the quality of its components, the manufacturer's reputation, and how well it is maintained.

A well-maintained water bottling machine that is manufactured with quality components can be very reliable and durable, and it can last for many years. However, a poorly manufactured or poorly maintained machine may have a shorter lifespan and be more prone to breakdowns.

To ensure the reliability and durability of your water bottling machine, it is essential to:

Choose a reputable manufacturer who uses quality components in their machines

Regularly maintain and service the machine to ensure it operates at optimal levels

Train the water bottling machine operators to use the machine properly and handle it carefully to avoid unnecessary wear and tear

If you follow these steps, your water bottling machine can be very reliable and durable, and it can provide you with many years of trouble-free operation.

What is the maintenance and upkeep required for a water bottling machine

Regular maintenance and upkeep are essential to ensure that a water bottling plant for sale operates efficiently and produces safe and high-quality bottled water. Here are some of the maintenance and upkeep tasks that are typically required for water bottling machines:

Regular cleaning:

The water bottling machine should be cleaned regularly to prevent the buildup of dirt and debris, which can affect the quality of the bottled water. The frequency of cleaning depends on the usage and the type of water being bottled.

Lubrication:

Moving parts of the water bottling machine should be lubricated periodically to ensure smooth and efficient operation.

Filter replacement:

Filters should be replaced at regular intervals to ensure that the water being bottled is free from impurities.

Inspection:

The water bottling machine should be inspected periodically to ensure that all parts are working properly and there are no signs of wear or damage.

Calibration:

The water bottling machine should be calibrated periodically to ensure that it is dispensing the correct amount of water.

Testing:

The bottled water should be tested regularly to ensure that it meets the required quality standards.

What is the warranty and after-sales support offered by Pestopack

The warranty and after-sales support offered by Pestopack for a water bottling machine including:

Warranty period:

The warranty period is 12 months. During the warranty period, Pestopack will repair or replace any defective parts or components free of charge.

Technical support:

Pestopack provides technical support to help troubleshoot any issues with the water bottling machine, either over the phone or through an online support portal.

Training and installation:

Pestopack provides training and installation services to help customers set up and operate the water bottling machine properly.

Parts availability:

Pestopack provides easy access to replacement parts and components.

Are there any safety considerations when using a water bottling machine

There are several safety considerations to keep in mind when using a water bottling machine. These include:

Electrical safety:

Water bottling machines are powered by electricity, and it's important to ensure that the electrical components are properly installed and maintained. Make sure to follow the manufacturer's instructions for installation, use, and maintenance to minimize the risk of electrical hazards.

Water bottling machine guards:

The water bottling machine should have appropriate guards in place to prevent accidents and protect operators from moving parts, hot surfaces, and other hazards.

Personal protective equipment (PPE):

Operators should wear appropriate PPE, such as gloves, safety glasses, and protective clothing, when operating the water bottling machine. This can help prevent injuries and exposure to chemicals and other hazards.

Quality control:

The water produced by the machine should be regularly tested to ensure that it meets quality and safety standards. The water bottling machine should be properly calibrated and maintained to ensure accurate and consistent results.

Operator training:

Operators should receive proper training on how to safely operate the machine, including how to handle chemicals, use PPE, and perform routine maintenance and cleaning tasks.

How to ensure the quality of water produced by a water bottling machine

To ensure the quality of water produced by a water bottling machine, here are some steps you can take:

Use a high-quality filtration system:

The filtration system is critical for removing impurities and contaminants from the water. Choose a water bottling machine that has a robust filtration system that meets your needs. Pestopack uses high quality stainless steel material for filters and tubes, and high quality RO membrane to ensure quality water.

Regularly test the water:

Regular water testing is essential for ensuring that the water produced by the machine meets quality and safety standards. You can perform water testing in-house or hire a third-party laboratory to do it for you.

Follow best practices for cleaning and sanitation:

Proper cleaning and sanitation are critical for maintaining the quality of the water produced by the machine. Follow the manufacturer's instructions for cleaning and sanitation, and establish a regular cleaning schedule to prevent the buildup of bacteria and other contaminants.

Ensure proper maintenance for water bottling machine:

Proper maintenance is essential for ensuring that the machine operates efficiently and produces high-quality water. Follow the manufacturer's instructions for maintenance, and address any issues promptly to prevent downtime and maintain the quality of the water produced.

Implement a quality control program:

A quality control program can help ensure that the water produced by the water bottle filling machine meets quality and safety standards. The program should include regular testing, monitoring, and documentation of results.

How long does it take to set up a water bottling machine

It will take 5-7 days to set up a water bottling machine, it will take 10-15 days to set up a complete water bottling plant for sale. It can vary depending on several factors, such as the complexity of the machine, the experience of the operators, and the availability of resources.

In general, the setup process involves assembling the machine, connecting it to a power source and water supply, calibrating the machine, and testing it to ensure that it's working properly.

It's important to note that proper training and experience are essential for ensuring that the machine is set up and operated correctly. Operators should receive thorough training on how to set up and operate the machine, as well as how to perform routine maintenance and troubleshooting. By following best practices for setup, operation, and maintenance, the water bottling machine can be set up quickly and efficiently, and the production of high-quality bottled water can begin.

How much does a water bottling machine cost

The cost of a water bottling machine can vary widely depending on several factors such as the type and size of the machine, the production capacity, the materials used.

Generally, smaller water bottling machines that are suitable for small-scale operations can cost around $10,000 to $30,000, while larger water bottling machines with higher production capacities can cost upwards of $100,000. If you want a complete water bottling line, the cost will be more higer. However, it's important to note that the cost of the machine is just one aspect of the overall cost of starting a water bottling business. Other factors such as raw materials, labor, utilities, and marketing expenses should also be taken into consideration.

Why choose water bottling machine manufacturer Pestopack

Pestopack is a water bottling machine manufacturer that offers a range of products and services to meet the needs of businesses in the beverage industry. Their water bottling machines are designed to provide efficient and reliable performance, with features such as automatic bottle loading and unloading, adjustable filling volumes, and high-speed production capabilities. Pestopack also offers customization options to meet the unique requirements of their customers, such as the ability to fill bottles of different sizes and shapes, and to add labeling and packaging capabilities.

In addition to our machines, Pestopack provides comprehensive customer support, including installation, training, and maintenance services. They also offer technical assistance and spare parts to ensure that our water bottling machines continue to perform optimally over time.

English

العربية

Français

Русский

Español

Português

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

қазақ

हिन्दी

فارسی

Kiswahili

українська

Հայերեն

עברית

বাংলা

සිංහල

Oʻzbekcha

Azərbaycan dili

Български

ქართული

guarani

ગુજરાતી

Hausa

Igbo

ಕನ್ನಡ

Kinyarwanda

Kurdî

Кыргызча

Oluganda

മലയാളം

मराठी

Afaan Oromoo

ਪੰਜਾਬੀ

Runasimi

chiShona

Soomaali

Тоҷикӣ

తెలుగు

ትግንያውያን

Türkmençe

Yorùbá

isiZulu