STEP 1: CONDUCT MARKET RESEARCH

STEP 2: DEVELP A BUSINESS PLAN

STEP 3: LEGAL COMPLIANCE AND LICENSES

STEP 4: SECURE A LOCATION AND EQUIPMENT

STEP 5: SOURCE HIGH-QUALITY RAW MATERIALS

STEP 6: DEVELOP AN EFFICIENT PRODUCTION PROCESS

STEP 7: BRANDING AND MARKETING

STEP 8: LAUNCH YOUR BUSINESS

STEP 9: SCALE AND DIVERSIFY

Starting an oil manufacturing business can be a lucrative venture, given the constant demand for various types of oils, such as cooking oil, essential oils, or lubricants. However, like any business, it requires careful planning, understanding of the market, and adherence to legal and environmental standards. Here's a step-by-step guide to help you embark on your oil manufacturing journey.

STEP 1: CONDUCT MARKET RESEARCH

Before diving into the oil manufacturing business, it's crucial to understand the market. Identify which type of oil has high demand in your target market. Are consumers looking for organic, non-GMO cooking oils, or is there a niche market for essential oils? Understanding your potential customers and your needs will help you tailor your products and marketing strategies effectively.

Identify Your Target Market

Begin by defining who your potential customers are. Are you targeting individual consumers, health enthusiasts, restaurants, or industrial users? Each segment has distinct preferences and requirements that will shape your product offerings.

Analyze Demand for Different Types of Oils

There's a plethora of oils in the market, each serving different purposes. Conduct a thorough analysis to determine which oils are in high demand within your target market. For instance, if you're considering the culinary sector, investigate whether there's a stronger market for olive oil, coconut oil, or perhaps sesame oil. Alternatively, if you're leaning towards essential oils, determine which ones (like lavender, eucalyptus, or tea tree) are more sought after.

Explore Trends and Consumer Preferences

Stay abreast of the latest trends in the oil industry. Are consumers leaning towards organic or non-GMO products? Is there a growing demand for cold-pressed oils? Understanding these trends can help you position your product to meet current consumer preferences.

Competitive Analysis

Identify your competitors and analyze their product offerings, market position, strengths, and weaknesses. Understanding what others in the space are doing can help you identify gaps in the market and opportunities for differentiation.

Regulatory Landscape

Get acquainted with the regulatory requirements specific to the type of oil you plan to manufacture. Different oils may have different standards and regulations that you need to comply with.

Pricing Strategy

Research the pricing landscape for the type of oil you wish to produce. Understanding how similar products are priced can help you develop a competitive pricing strategy that appeals to your target market while ensuring profitability.

Distribution Channels

Investigate the most effective distribution channels for your oil products. Would your target market prefer purchasing online, in specialty stores, or in supermarkets? The choice of distribution channels will significantly impact your marketing and sales strategies.

Market Research Methods

Utilize various market research methods to gather data. This can include surveys, focus groups, interviews, and analyzing existing research reports. Leveraging social media and online forums can also provide insights into consumer preferences and behavior.

STEP 2: DEVELP A BUSINESS PLAN

A comprehensive business plan is essential for any successful business. It should outline your business objectives, target market, competition analysis, marketing strategy, and financial projections. Your business plan will serve as a roadmap and can help you secure financing if needed.

Executive Summary

This section provides a concise overview of your business and its mission. Although it appears first in the business plan, it's typically written last. It should summarize key points such as your business idea, the products you plan to manufacture, your target market, and your financial goals.

Business Objectives

Clearly state what you aim to achieve with your oil manufacturing business in the short and long term. Objectives should be specific, measurable, achievable, relevant, and time-bound (SMART).

Company Description

Offer a detailed description of your business. Include the legal structure (e.g., LLC, corporation), the nature of the business, the specific types of oils you plan to manufacture, and the unique aspects that give your business a competitive edge.

Market Analysis

Delve into the findings from your market research. Describe your target market's characteristics, size, and growth potential. Discuss industry trends, customer needs, and how your business will meet those needs. This section should also include a thorough competitive analysis, highlighting your competitors' strengths and weaknesses and your differentiation strategy.

Product Line

Describe in detail the oil products you plan to manufacture. Include information about the production process, the source of your raw materials, and any unique features or benefits of your products. If you plan to expand your product line in the future, mention those plans as well.

Marketing and Sales Strategy

Outline how you intend to attract and retain customers. Describe your marketing activities, sales strategy, pricing model, advertising, promotions, and distribution channels. Explain how you will measure the effectiveness of your marketing efforts.

Operational Plan

Detail the day-to-day operations of your oil manufacturing business. This includes the production process, equipment needs, labor requirements, supplier information, and facility requirements. Also, discuss how you will ensure quality control and compliance with relevant regulations.

Management and Organization

Describe the structure of your business, detailing the roles and responsibilities of the management team and key employees. Include information about their experience and how it will contribute to the success of your business.

Financial Plan

This is one of the most critical sections of your business plan. It should include detailed financial projections, including startup costs, operating costs, revenue projections, profit and loss forecasts, cash flow statements, and balance sheets. If you're seeking financing, clearly state the amount needed and how it will be used.

Appendices

Include any additional information that supports your business plan. This could be resumes of your management team, product pictures, marketing materials, detailed market studies, or relevant legal documents.

STEP 3: LEGAL COMPLIANCE AND LICENSES

Obtaining the necessary permits and licenses is crucial in the oil manufacturing industry due to its potential environmental impact. Ensure compliance with local, state, and federal regulations regarding health, safety, and environmental protection. This might include obtaining a business license, a food operator's license if you're producing cooking oil, and adhering to FDA regulations for product safety and labeling.

STEP 4: SECURE A LOCATION AND EQUIPMENT

Choose a location that complies with zoning laws and is suitable for oil production. The space should accommodate your manufacturing equipment, storage, and office space. You will need to purchase or lease machinery for extracting, refining, and bottling oil, depending on your business scale and the type of oil you plan to produce.

Location Selection

Zoning Compliance: Ensure the selected location is zoned for industrial or manufacturing use. Check with local authorities to confirm that your business activities are allowed in the chosen area.

Accessibility: Consider the ease of access for suppliers and distributors. Proximity to major roads or highways can reduce transportation costs and facilitate timely deliveries.

Environmental Considerations: Evaluate the environmental impact of your manufacturing process and ensure the location has adequate measures for waste disposal, especially if your process generates significant byproducts or waste.

Expansion Potential: Think about the future. If your business grows, will the location allow for expansion, or will you need to relocate?

Cost: Balance the cost of the location with its benefits. Prime locations may offer more visibility and accessibility but at a higher cost.

Facility Requirements

Space: Determine how much space you need for your manufacturing process, storage of raw materials and finished products, offices, and any other necessary areas like laboratories for quality control.

Utilities: Ensure the facility has the necessary utilities for your manufacturing process, including adequate water supply, electricity, gas, and waste disposal systems.

Safety: Evaluate the facility for occupational safety. Ensure there is adequate ventilation, fire safety measures, and space for safe operation of machinery.

Equipment Acquisition

Extraction Equipment: Depending on the type of oil you are producing, you may need cold press machines, solvent extraction units, or steam distillation equipment.

Refining Equipment: If your manufacturing process includes refining the oil, you'll need equipment for filtering, degumming, neutralizing, bleaching, and deodorizing.

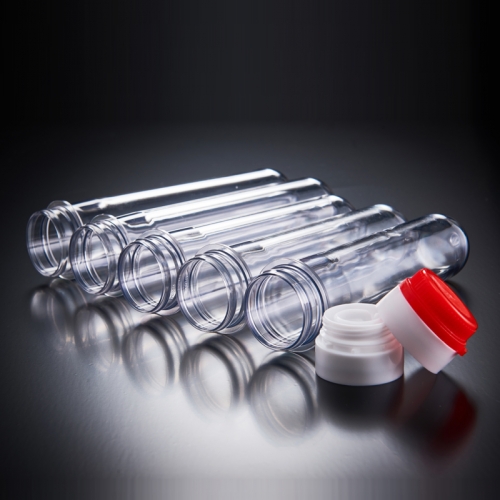

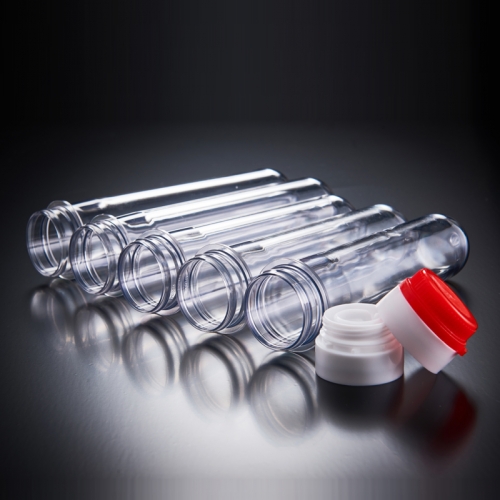

Bottling and Packaging: Acquire machinery for bottling, capping, labeling, and packaging your oil products. The type of machinery will depend on your packaging design and materials. Our company Pestopack is one of oil filling machine manufactures in China, specializes in providing automated oil filling machines that are designed to enhance production efficiency. Our machines are engineered to handle a variety of oil types and packaging formats, ensuring precise filling, capping, and labeling. By integrating Pestopack's oil filling machines into your production line, you can achieve a more streamlined, efficient, and reliable bottling process, contributing to overall productivity and product consistency.

Packaging Material: Select appropriate packaging materials that protect the oil's quality, extend its shelf life, and comply with regulatory standards.

Quality Control: Invest in equipment for in-house quality testing, which may include spectrophotometers, chromatography systems, and moisture analyzers, depending on the oil type and required testing.

Maintenance: Consider the maintenance requirements of the equipment. Regular maintenance ensures longevity and consistent performance of your machinery. If you want to know price of oil bottling machine, please read this article Ultimate Guide to Navigating Oil Filling Machine Price for more information.

Technical Expertise

Training: Ensure that your staff is adequately trained to operate the machinery. This includes understanding the operational procedures, safety protocols, and maintenance routines.

Technical Support: Establish relationships with equipment suppliers or technical experts who can provide support in case of breakdowns or technical issues.

STEP 5: SOURCE HIGH-QUALITY RAW MATERIALS

The quality of your oil significantly depends on the raw materials you use. Whether you're extracting oil from seeds, nuts, fruits, or other sources, ensure you're sourcing high-quality, preferably organic, raw materials. Establishing strong relationships with reliable suppliers is key to maintaining product quality and consistency.

STEP 6: DEVELOP AN EFFICIENT PRODUCTION PROCESS

Design an efficient and safe production process to maximize yield and maintain quality. This includes the extraction, refining, and bottling stages. Implementing quality control measures throughout the production process is essential to ensure the final product meets industry standards and customer expectations.

Process Design

Flowcharting: Begin by creating a detailed flowchart of the entire production process, from raw material intake to final product packaging. This visual representation helps identify potential bottlenecks, redundancies, or inefficiencies.

Segmentation: Break down the production process into distinct stages, such as extraction, refining, and bottling. Define the specific activities, inputs, and outputs for each stage.

Extraction Process

Method Selection: Choose the most suitable extraction method (e.g., cold pressing, solvent extraction, steam distillation) based on the type of oil and the desired quality. Each method has its own efficiency and impact on the oil's characteristics.

Optimization: Optimize the extraction parameters, such as temperature, pressure, and time, to maximize yield while maintaining quality.

Refining Process

Purification Steps: Develop a sequence of refining steps, which may include degumming, neutralizing, bleaching, and deodorizing, depending on the oil type and required purity.

Quality Retention: Ensure that the refining process maintains the essential characteristics of the oil, such as flavor, color, and nutritional value, while removing undesirable components.

Bottling and Packaging

Automation: Consider automating the bottling and packaging process to increase efficiency, accuracy, and consistency. Pestopack is a renowned manufacturer specializing in the development and production of oil filling machine, catering to the diverse needs of the oil manufacturing industry. Our oil filling machines are designed to streamline the production process, enhancing efficiency, precision, and reliability in the bottling phase of manufacturing. Our oil filling machines are adaptable to various types of oils, from edible cooking oils to essential oils and lubricants, accommodating different viscosities and chemical properties. These machines are engineered for accuracy, ensuring that each container is filled with the exact amount of oil, minimizing waste and ensuring consistency across products. We offer customizable options for oil filling machines. This flexibility allows businesses to tailor the equipment to your specific production line requirements. By incorporating Pestopack's oil filling machines into your production lines, businesses can achieve greater control over bottling processes, enhance efficiency, and ensure a high-quality end product, aligning with your goals for growth and customer satisfaction in the competitive oil manufacturing market.

Quality Control

Testing Protocols: Implement rigorous testing protocols at various stages of the production process to monitor the quality of the oil. This might include testing for purity, acidity, color, and other relevant parameters.

Feedback Loop: Establish a feedback loop where results from quality control tests are used to adjust and improve the production process continuously.

Safety and Compliance

Regulatory Adherence: Ensure that the production process complies with all relevant health, safety, and environmental regulations.

Worker Training: Train employees on safe operation procedures, emergency response, and best practices to minimize the risk of accidents and ensure a safe working environment.

Waste Management

Byproduct Utilization: Identify ways to utilize byproducts of the oil manufacturing process, reducing waste and potentially creating additional revenue streams.

Disposal Plans: Develop environmentally responsible plans for disposing of waste materials that cannot be reused or recycled.

Continuous Improvement

Performance Monitoring: Regularly monitor the efficiency and effectiveness of the production process, identifying areas for improvement.

Innovation: Stay informed about new technologies and methods that can enhance your production process, reduce costs, or improve product quality.

STEP 7: BRANDING AND MARKETING

Create a strong brand identity that resonates with your target audience. Your branding should reflect the quality and uniqueness of your oil products. Develop an effective marketing strategy that includes digital marketing, trade shows, and retail partnerships to reach your target customers. Educate your customers about the benefits and uses of your oil to create demand.

STEP 8: LAUNCH YOUR BUSINESS

Once everything is in place, launch your business. Start production, initiate your marketing campaigns, and begin selling your oil. Monitor your business closely, gather customer feedback, and adjust your strategies as needed to grow your business.

STEP 9: SCALE AND DIVERSIFY

As your business grows, consider scaling up your production and diversifying your product range to include different types of oils or related products. Always keep an eye on market trends and customer preferences to adapt your business accordingly.

Starting an oil manufacturing business requires dedication, research, and a clear strategy. By understanding your market, complying with regulations, ensuring product quality, and effectively branding and marketing your products, you can establish a successful oil manufacturing business. Contact us for more information of oil filling machines.

English

العربية

Français

Русский

Español

Português

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

қазақ

हिन्दी

فارسی

Kiswahili

українська

Հայերեն

עברית

বাংলা

සිංහල

Oʻzbekcha

Azərbaycan dili

Български

ქართული

guarani

ગુજરાતી

Hausa

Igbo

ಕನ್ನಡ

Kinyarwanda

Kurdî

Кыргызча

Oluganda

മലയാളം

मराठी

Afaan Oromoo

ਪੰਜਾਬੀ

Runasimi

chiShona

Soomaali

Тоҷикӣ

తెలుగు

ትግንያውያን

Türkmençe

Yorùbá

isiZulu