Understanding the Egyptian Bottled Water Market

Planning Your Water Bottling Line

Choosing the Right Equipment

Compliance with Egyptian Regulations

Estimating Costs for a Water Bottling Line in Egypt

Selecting a Reliable Equipment Supplier

Marketing and Distribution Strategies

Why Choose PestoPack

Setting up a water bottling line in Egypt requires careful planning, compliance with regulations, and the right equipment to meet market demands. This process begins with understanding the growing opportunities in Egypt's bottled water industry, selecting advanced technology, and adopting sustainable practices to ensure long-term success.

Understanding the Egyptian Bottled Water Market

Egypt's bottled water market is one of the fastest-growing in Africa, driven by increasing urbanization and demand for safe drinking water. Key points to consider include:

Market Demand: High demand in urban and tourist areas, with the Egyptian bottled water market projected to grow at a compound annual growth rate (CAGR) of over 7% in the next five years. Factors driving this growth include a rising middle class, a hot climate, and growing concerns over the safety of tap water.

Competition: Key players include Nestlé Pure Life and Baraka, which dominate the market with extensive distribution networks. Meanwhile, emerging local brands are targeting niche markets like premium or flavored water, appealing to younger and health-conscious consumers.

Consumer Preferences: Consumers show a strong preference for small-sized bottles (500ml-1.5L) due to their convenience and portability. Additionally, there is increasing interest in eco-friendly packaging solutions, such as biodegradable bottles, driven by growing environmental awareness.

Planning Your Water Bottling Line

Planning a water bottling plant for sale involves several critical steps to ensure efficiency and scalability. Start by determining your production capacity based on demand forecasts—a capacity range of 2,000 to 12,000 bottles per hour is common for medium-sized operations in Egypt. Factor in your target market's preferences for bottle sizes and types, such as PET or glass.

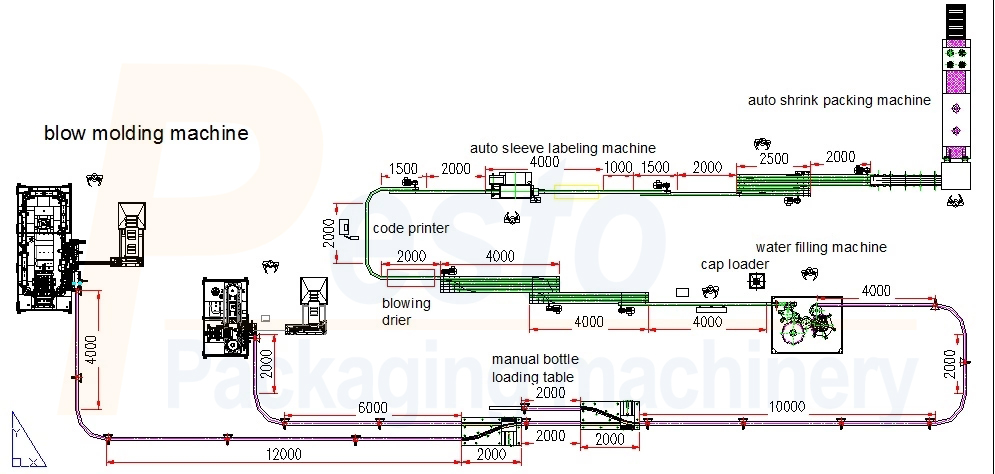

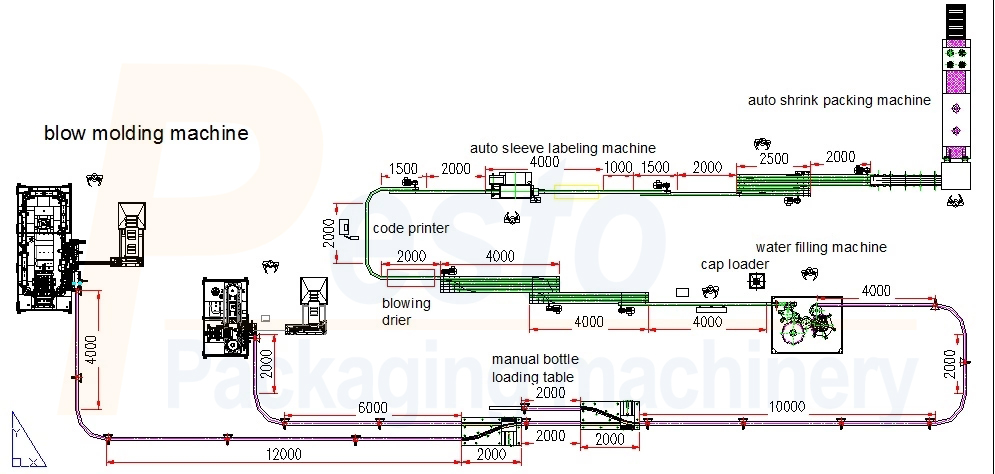

When designing the factory layout, focus on optimizing workflow to minimize bottlenecks. For instance, a linear production line might suit smaller facilities, while a U-shaped configuration could better utilize larger spaces. Include designated zones for machinery, storage, and quality control.

Budgeting is another essential component. Allocate resources not only for purchasing equipment but also for operational costs like utilities and labor. Consulting with our experts can provide a more accurate cost breakdown tailored to your specific needs.

Choosing the Right Equipment

Selecting suitable equipment is crucial for a smooth production process. Key machines include:

Water Purification System (2-50T): Ensures water meets safety and quality standards by removing contaminants through processes such as reverse osmosis, UV sterilization, and carbon filtration.

Bottle Blowing Machine: Available in semi-automatic and full-automatic models to produce PET bottles in various sizes, reducing reliance on external suppliers.

3-in-1 Water Filling Machine: A compact and efficient water filling machinethat integrates bottle rinsing, filling, and capping into one machine, saving space and improving workflow.

Labeling Machine: Offers multiple options for labeling, including OPP labeling, shrink sleeve labeling, and sticker labeling, allowing customization based on brand requirements.

Laser Printer: Adds production dates, batch numbers, and expiration dates to bottles with high precision.

Packing Machine: Includes shrink sleeving machines for compact packaging or carton packing machines for secure transportation.

Conveyor System: Ensures smooth and efficient movement of bottles between different stages of the production line.

Each piece of equipment should be selected based on production capacity, bottle size, and automation level to ensure cost-effectiveness and scalability.

Compliance with Egyptian Regulations

Egypt has strict regulations for bottled water production. Ensure compliance by:

Using Food-Grade Materials: Ensure bottles and caps meet food safety standards.

Obtaining Necessary Certifications: Work with the Egyptian Organization for Standardization and Quality (EOS) to acquire the required certifications for your products. This includes water quality testing, factory inspections, and labeling approvals.

Meeting Labeling Requirements: Labels must include information in Arabic, such as the water source, production date, expiry date, and batch number.

Health and Safety Compliance: Adhere to Ministry of Health guidelines, including hygiene standards for production facilities and storage.

Follow these steps to streamline the certification process:

1. Submit water quality samples for testing to an authorized laboratory.

2. Apply for EOS certification with all necessary documentation.

3. Schedule an inspection of your production line and facilities.

4. Address any feedback or required adjustments from the inspection.

Estimating Costs for a Water Bottling Line in Egypt

The cost of setting up a water bottling line depends on several factors, including:

Equipment: Prices range from $50,000 for small-scale semi-automated lines to $300,000 or more for fully automated high-capacity systems. For example, a water bottling line producing 2,000 bottles per hour (BPH) may cost around $50,000, while a 12,000 BPH water bottling machine with advanced automation could exceed $300,000.

Utilities: Electricity, water, and labor costs vary depending on the production scale. A small-scale operation may require $1,000 per month in utilities, while larger setups could spend upwards of $5,000.

Raw Materials: Costs for bottles, caps, and labels can fluctuate based on production volume. For instance, producing 500ml bottles may cost $0.05 per unit in raw materials.

By carefully assessing production goals and automation levels, businesses can optimize costs and ensure a sustainable return on investment.

Selecting a Reliable Water Bottling Equipment Supplier

Partnering with a trustworthy supplier ensures quality and after-sales support. Consider:

Experience: Look for water bottling equipment suppliers with a proven track record of delivering water bottling solutions.

Customization: Choose a supplier who can tailor equipment to your specific production requirements and factory layout.

Support: Ensure the supplier offers technical assistance, spare parts availability, and training services.

Checklist for Evaluating Water Bottling Machine Suppliers

Does the water filling machine supplier have experience with similar-sized projects in Egypt or the Middle East?

Can the water bottling line supplier provide references from satisfied customers?

Is the equipment compatible with local regulations and water quality standards?

Does the water filling machine manufacturer offer a warranty and after-sales service package?

Are spare parts easily available and reasonably priced?

Can the water bottling machine supplier assist with factory layout planning and integration of new equipment?

By following this checklist, you can ensure that your chosen supplier aligns with your business goals and operational needs.

Marketing and Distribution Strategies

Effective marketing and distribution are vital for success:

Distribution Channels: Supermarkets, local stores, and online platforms are key distribution points. For example, partnering with large chains like Carrefour or local Egyptian grocery networks can ensure widespread availability.

Branding: Use appealing labels and eco-friendly packaging to stand out in a competitive market. For instance, brands that highlight "purity" and "local sourcing" often perform well in Egypt.

Promotions: Offer discounts or bundle deals to attract customers. A notable campaign involved a bottled water brand offering free bottles with every multi-pack purchase during the summer season, significantly boosting sales.

Sustainability Practices

Adopting sustainable practices not only helps the environment but also attracts eco-conscious consumers. Consider:

Eco-Friendly Bottles: Use recyclable or biodegradable materials to reduce environmental impact. For instance, some leading companies in the industry have adopted lightweight PET bottles to minimize plastic usage.

Energy Efficiency: Incorporate solar panels or energy-saving equipment to lower production costs and reduce carbon emissions. One prominent Egyptian bottling company reduced its energy consumption by 20% by switching to solar-powered machinery.

Waste Management: Implement systems for reducing and recycling waste. An example is a company that partnered with local recycling facilities to repurpose used bottles into new packaging materials.

Why Choose PestoPack

At PestoPack, we pride ourselves on delivering comprehensive solutions for water bottling lines that cater to the unique needs of businesses in Egypt and beyond. Here’s why PestoPack stands out:

Turnkey Solutions: We handle everything from initial consultation, factory layout design, equipment manufacturing, and installation to staff training and ongoing support.

Advanced Technology: Our equipment integrates the latest innovations to enhance efficiency, precision, and sustainability.

Proven Expertise: With over 15 years of experience and installations in 30+ countries, we understand the complexities of the bottled water industry.

Customer-Centric Approach: We prioritize your success by providing tailored solutions and exceptional after-sales service.

Let PestoPack be your partner in building a successful water bottling business in Egypt. Contact us today to start your journey toward efficiency and growth.

English

العربية

Français

Русский

Español

Português

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

қазақ

हिन्दी

فارسی

Kiswahili

українська

Հայերեն

עברית

বাংলা

සිංහල

Oʻzbekcha

Azərbaycan dili

Български

ქართული

guarani

ગુજરાતી

Hausa

Igbo

ಕನ್ನಡ

Kinyarwanda

Kurdî

Кыргызча

Oluganda

മലയാളം

मराठी

Afaan Oromoo

ਪੰਜਾਬੀ

Runasimi

chiShona

Soomaali

Тоҷикӣ

తెలుగు

ትግንያውያን

Türkmençe

Yorùbá

isiZulu