1. Formulation Development

2. Weighing and Mixing

3. Emulsification

4. Cooling and Homogenization

5. Addition of Active Ingredients and Preservatives

6. Quality Control

7. Filling

8. Sealing

9. Labeling

10. Packaging

Conclusion

Producing face cream involves a meticulous process to ensure the product's quality, safety, and effectiveness. This comprehensive procedure requires attention to detail at every stage, from selecting the finest raw materials to ensuring the final product is perfectly packaged. Each step plays a crucial role in maintaining the integrity of the face cream, ensuring it meets high standards for consumer use. Below is a detailed guide on how face cream is made, highlighting each phase from the careful selection of raw materials to the precise formulation, thorough quality control, and finally, the efficient and hygienic packaging process. This guide aims to provide an in-depth understanding of the intricate process behind producing a high-quality face cream that is safe, effective, and ready for the market.

1. Formulation Development

The journey of creating face cream begins with developing the right formulation, a process that lays the foundation for the entire product. This crucial step involves the careful selection and combination of various ingredients, each chosen for its specific beneficial properties and the desired characteristics of the final product.

Emulsifiers are selected to ensure the oil and water phases blend smoothly, providing a stable and consistent texture. Thickeners are added to achieve the desired viscosity and to enhance the cream's feel on the skin. Humectants play a vital role in attracting and retaining moisture, ensuring the skin remains hydrated. Emollients are included to soften and soothe the skin, creating a protective barrier that locks in moisture.

Active ingredients such as vitamins, antioxidants, and botanical extracts are meticulously chosen for their targeted benefits. Vitamins, like Vitamin C and Vitamin E, are added for their antioxidant properties, helping to protect the skin from environmental damage and promoting a healthy complexion. Botanical extracts, sourced from natural plants, offer various skin benefits, from soothing inflammation to providing essential nutrients.

The formulation development phase is a collaborative effort between chemists, dermatologists, and product developers, ensuring that the final product is not only effective but also safe and pleasant to use. Through rigorous testing and iterations, the formulation is refined until it meets all desired criteria, setting the stage for the subsequent steps in the production process.

2. Weighing and Mixing

Once the formulation is finalized, the production process moves to the critical phase of weighing and mixing the ingredients. This step is essential to ensure that each batch of face cream maintains consistency and quality. The ingredients are precisely weighed according to the meticulously developed recipe, with each component measured to the exact gram to guarantee the correct proportions.

The mixing process begins by separately combining the water-soluble and oil-soluble ingredients. Water-soluble ingredients, which may include humectants, thickeners, and certain active ingredients, are mixed in one vessel. In another vessel, the oil-soluble ingredients, such as emollients, oils, and some vitamins, are combined. This segregation is necessary because water and oil do not naturally mix; they require specific conditions and techniques to form a stable blend.

Both the water phase and the oil phase are then heated to a specific temperature, usually around 70-80 degrees Celsius (158-176 degrees Fahrenheit). Heating these phases is crucial as it helps to dissolve certain ingredients and also facilitates the emulsification process. Once both phases reach the desired temperature, they are gradually combined. This is done using high-shear mixers, which apply intense mechanical force to break down the oil droplets into tiny particles, allowing them to disperse evenly throughout the water phase.

The result of this process is a stable emulsion, a homogeneous mixture where the oil and water phases are uniformly distributed. This emulsion is what gives the face cream its smooth, luxurious consistency. The careful control of temperature, mixing speed, and time is essential to ensure the final product is not only stable but also has the desired texture and efficacy. This phase lays the groundwork for a high-quality face cream that meets the formulated standards.

3. Emulsification

Emulsification is a crucial step in the production of face cream, where the previously prepared oil and water phases are blended together to form a cohesive and stable mixture. This process is vital to ensure that the face cream maintains its smooth texture and does not separate over time, which would compromise its quality and effectiveness.

The emulsification process begins by introducing the oil phase into the water phase. This is typically done using high-shear mixers, which are specialized equipment designed to apply intense mechanical force to the mixture. The high-shear mixers operate at high speeds, generating sufficient energy to break down the oil droplets into microscopic sizes. These tiny droplets are then evenly dispersed throughout the water phase, creating a uniform emulsion.

The effectiveness of this process relies on the precise control of various parameters, including mixing speed, temperature, and the duration of mixing. High shear force ensures that the oil droplets are small enough to remain suspended in the water phase, preventing them from coalescing and separating out. This results in a stable emulsion with a smooth and creamy consistency, which is essential for a high-quality face cream.

Additionally, emulsifiers play a critical role during this step. These ingredients are added to the mixture to help stabilize the emulsion by reducing the surface tension between the oil and water phases. Common emulsifiers used in face cream formulations include lecithin, polysorbates, and cetyl alcohol, among others. They work by forming a protective barrier around the oil droplets, preventing them from coming together and separating from the water phase.

Emulsification is a delicate balance of science and art, requiring careful monitoring and adjustments to achieve the perfect consistency. The end result is a face cream that is not only aesthetically pleasing but also effective in delivering its beneficial ingredients to the skin. This stable emulsion ensures that the active ingredients are evenly distributed throughout the product, providing consistent results with every use.

4. Cooling and Homogenization

After the emulsification process, the next critical steps in producing face cream are cooling and homogenization. These steps are essential to ensure the final product achieves the desired texture, consistency, and stability.

Once the oil and water phases have been successfully emulsified, the mixture is gradually cooled to room temperature. Cooling is done in a controlled manner while continuing to mix the cream to maintain the uniform distribution of ingredients and to prevent any separation. This gradual reduction in temperature helps to solidify the structure of the emulsion, locking in the smooth texture achieved during emulsification.

During the cooling process, continuous mixing is vital to ensure that the temperature is evenly distributed throughout the mixture. This prevents the formation of lumps and maintains the consistency of the cream. The mixing also helps to dissipate any heat generated during the emulsification process, allowing the cream to cool uniformly.

Homogenization often takes place during or after the cooling phase to further refine the texture of the cream. This process involves forcing the mixture through a narrow space, which applies high pressure to break down any remaining larger particles and droplets into even smaller sizes. Homogenization enhances the cream's smoothness and ensures that the active ingredients are evenly distributed throughout the product.

The result of homogenization is a face cream with a highly uniform and smooth texture, free of any graininess or unevenness. This step is crucial for creating a luxurious feel on the skin and for ensuring that the cream spreads easily and absorbs well. Homogenization also helps to enhance the cream's stability, preventing the separation of oil and water phases over time and ensuring that the product remains effective and aesthetically pleasing throughout its shelf life.

By carefully controlling the cooling and homogenization processes, manufacturers can produce a high-quality face cream that delivers consistent performance, feels delightful on the skin, and meets the rigorous standards of quality and effectiveness required in the skincare industry.

5. Addition of Active Ingredients and Preservatives

Once the base cream is prepared and has cooled to the appropriate temperature, the next step involves the addition of active ingredients, fragrances, and preservatives. This stage is crucial for enhancing the efficacy, appeal, and shelf life of the face cream.

Active Ingredients:

Active ingredients are added to deliver specific benefits to the skin. These can include vitamins, peptides, antioxidants, and botanical extracts. For example, Vitamin C is often added for its brightening and anti-aging properties, while hyaluronic acid is included for its excellent moisturizing capabilities. Because these ingredients are typically sensitive to heat, they are added after the mixture has cooled to preserve their potency and effectiveness.

Fragrances:

Fragrances are introduced to enhance the sensory experience of using the face cream. These can range from natural essential oils to synthetic fragrance compounds. The choice of fragrance depends on the desired scent profile of the final product and consumer preferences. Adding fragrances at this stage ensures they blend well without degrading due to high temperatures.

Preservatives:

Preservatives are essential for preventing microbial contamination and extending the shelf life of the face cream. Common preservatives include parabens, phenoxyethanol, and natural alternatives like rosemary extract. These components are carefully selected to ensure they are effective at low concentrations and compatible with the other ingredients in the formulation.

Mixing:

After the addition of these sensitive components, the mixture is gently stirred to ensure uniform distribution throughout the base cream. This step requires careful handling to avoid introducing air bubbles and to maintain the smooth texture of the product.

The meticulous addition of active ingredients, fragrances, and preservatives is a delicate yet vital phase in the production of face cream. It ensures that the final product not only delivers the promised skincare benefits but also provides a pleasant user experience and remains safe and stable over time.

6. Quality Control

The final face cream undergoes a series of rigorous quality control tests to ensure it meets all safety and quality standards before it is approved for packaging. This crucial step is designed to verify that the product is safe, effective, and consistent with the desired specifications.

PH Testing:

The PH of the face cream is tested to ensure it is within the optimal range for skin compatibility. The PH level affects the product's stability and its interaction with the skin. A balanced pH ensures the cream is gentle and non-irritating, making it suitable for daily use.

Viscosity Measurement:

The viscosity of the cream is measured to confirm that it has the right consistency. Viscosity affects how the cream spreads and absorbs into the skin. Ensuring the correct viscosity is crucial for user satisfaction and the overall effectiveness of the product.

Microbial Testing:

Microbial testing is conducted to ensure the face cream is free from harmful bacteria, yeast, and mold. This is a critical step in ensuring the product is safe for consumers. The cream is tested for microbial contamination both immediately after production and after being stored under various conditions to simulate real-world use.

Stability Testing:

Stability testing evaluates how the face cream performs over time and under different environmental conditions. This includes testing the product's physical, chemical, and microbiological stability. The cream is subjected to accelerated aging conditions to predict its shelf life and to ensure it remains stable and effective throughout its intended use period.

Additional Tests:

Depending on the formulation and intended use, additional tests may be performed. These can include sensory evaluations, which assess the product's appearance, texture, and scent, and efficacy tests, which measure the performance of active ingredients.

Each batch of face cream must pass all these quality control tests before it can be approved for packaging. This thorough testing process ensures that every jar of face cream meets the highest standards of safety and quality, providing consumers with a reliable and effective skincare product. By adhering to stringent quality control protocols, manufacturers can maintain their reputation for excellence and ensure customer satisfaction.

7. Filling

Once the face cream has passed all quality control tests, it is transferred to the filling station. Here, the cream is dispensed into jars, tubes, or bottles using specialized filling machines designed to ensure precision and consistency. Precision is paramount during this stage to avoid overfilling or underfilling, which can not only affect the product's shelf life but also its overall presentation. Advanced filling machines, such as our state-of-the-art cream filling machine, are used to achieve accurate fill levels, ensuring each container holds the correct amount of product. This step also involves maintaining strict hygiene standards to prevent contamination and to ensure that the face cream remains safe and effective for consumer use.

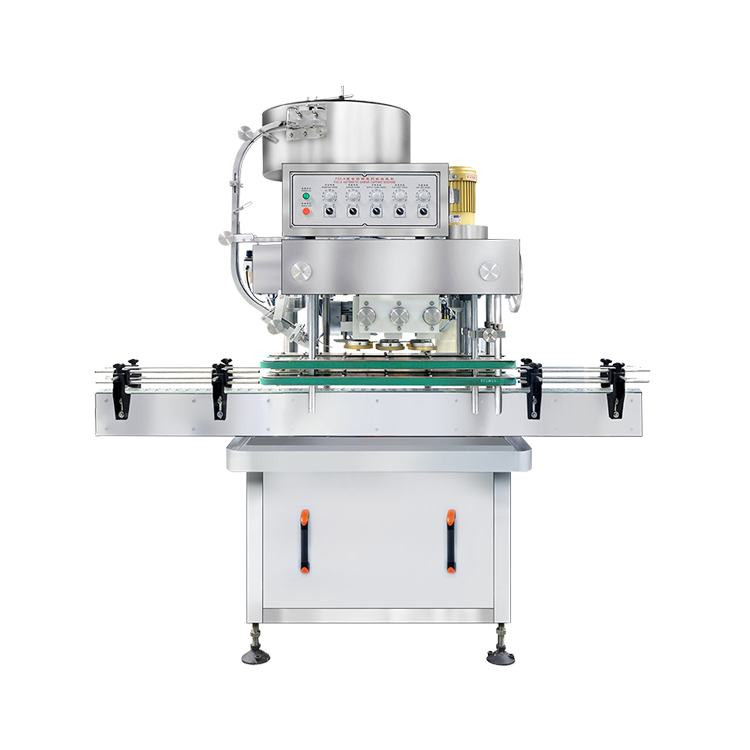

8. Sealing

After liquid bottle filling machine, the containers are moved to the sealing station. Here, each jar, tube, or bottle is securely sealed to protect the product from environmental factors and to maintain its integrity. Sealing can involve applying lids, caps, or tamper-evident seals, depending on the type of packaging used. This step is crucial to ensure the product remains uncontaminated and fresh, preserving its quality until it reaches the consumer.

9. Labeling

Following the sealing process, the containers proceed to the labeling station. Labels are applied to each container, providing essential information such as the product name, ingredients, usage instructions, and expiration date. The labeling process is automated to ensure precision and consistency, making sure that every product looks professional and meets regulatory requirements. Accurate labeling is essential for both marketing and legal compliance, as it informs consumers about the product and its proper use.

10. Packaging

The final step in the production process is packaging the sealed and labeled containers into cartons or boxes, ready for distribution. This involves carefully arranging the products to prevent damage during transportation. The packaging process is designed to be efficient, ensuring that large quantities of the product can be handled quickly and safely. Packaging materials are selected to provide adequate protection while also being environmentally friendly whenever possible. Once packed, the cartons are sealed and labeled for shipment, ensuring that the face cream reaches consumers in perfect condition.

Conclusion

Producing and packaging face cream involves a series of meticulous steps to ensure the product's quality and effectiveness. Each stage, from formulation development to the final packaging, requires precision and attention to detail. By incorporating advanced machinery like our cream filling machine, manufacturers can achieve greater precision, efficiency, and hygiene in their operations. This leads to superior products that meet the high standards of today's skincare market, providing consumers with reliable, high-quality face creams that deliver on promises.

English

العربية

Français

Русский

Español

Português

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

қазақ

हिन्दी

فارسی

Kiswahili

українська

Հայերեն

עברית

বাংলা

සිංහල

Oʻzbekcha

Azərbaycan dili

Български

ქართული

guarani

ગુજરાતી

Hausa

Igbo

ಕನ್ನಡ

Kinyarwanda

Kurdî

Кыргызча

Oluganda

മലയാളം

मराठी

Afaan Oromoo

ਪੰਜਾਬੀ

Runasimi

chiShona

Soomaali

Тоҷикӣ

తెలుగు

ትግንያውያን

Türkmençe

Yorùbá

isiZulu