ESSENTIAL OIL FILLING MACHINE APPLICATION

Formulation of Essential Oils:

1. Pure and Concentrated: Essential oils are formulated to be pure and highly concentrated, ensuring that you experience the full spectrum of their natural properties.

2. Blending Capabilities: Essential oils can be blended together to create custom fragrances and therapeutic combinations, offering endless possibilities for tailored formulations.

3. Safety and Purity: Essential oils are rigorously tested for purity and potency, ensuring they are free from contaminants and additives.

Viscosity Values of Essential Oils:

1. Low Viscosity Oils: Some essential oils, like citrus oils, typically have low viscosity, which means they are thin and flow easily. These oils are well-suited for applications such as diffusing and massage.

2. Medium Viscosity Oils: Many essential oils fall into the medium viscosity range, offering a balance between thickness and flow. These oils are versatile and can be used in various applications, from skincare to candle-making.

3. High Viscosity Oils: Essential oils with higher viscosity levels are thicker and less fluid. They are often used in products that require a more substantial fragrance, such as perfumes and solid balms.

Matching the formulation and viscosity with the appropriate essential oil filling machine is essential for efficient and accurate production. It ensures that the essential oil is dispensed smoothly into the bottles, minimizing wastage and maintaining product quality.

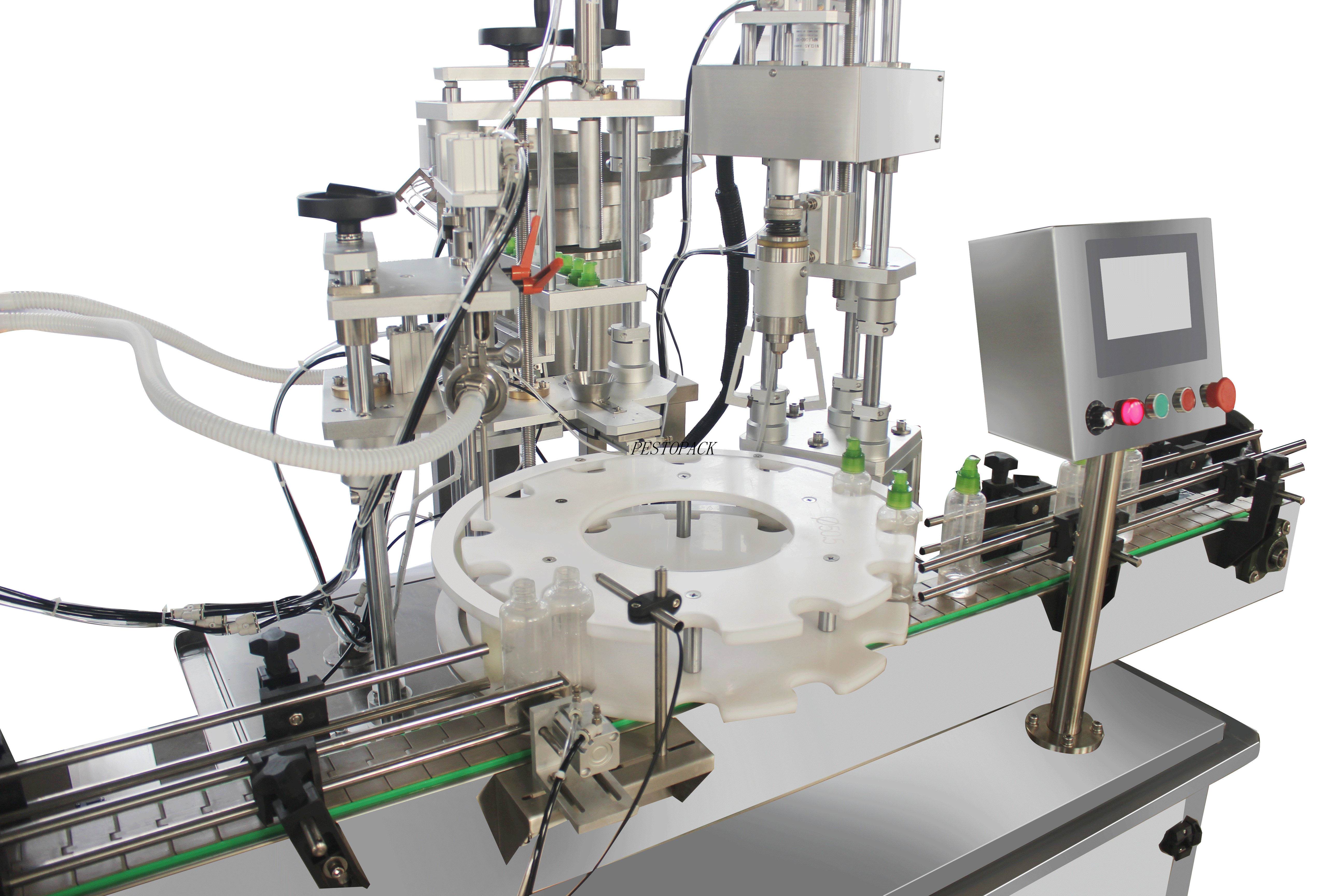

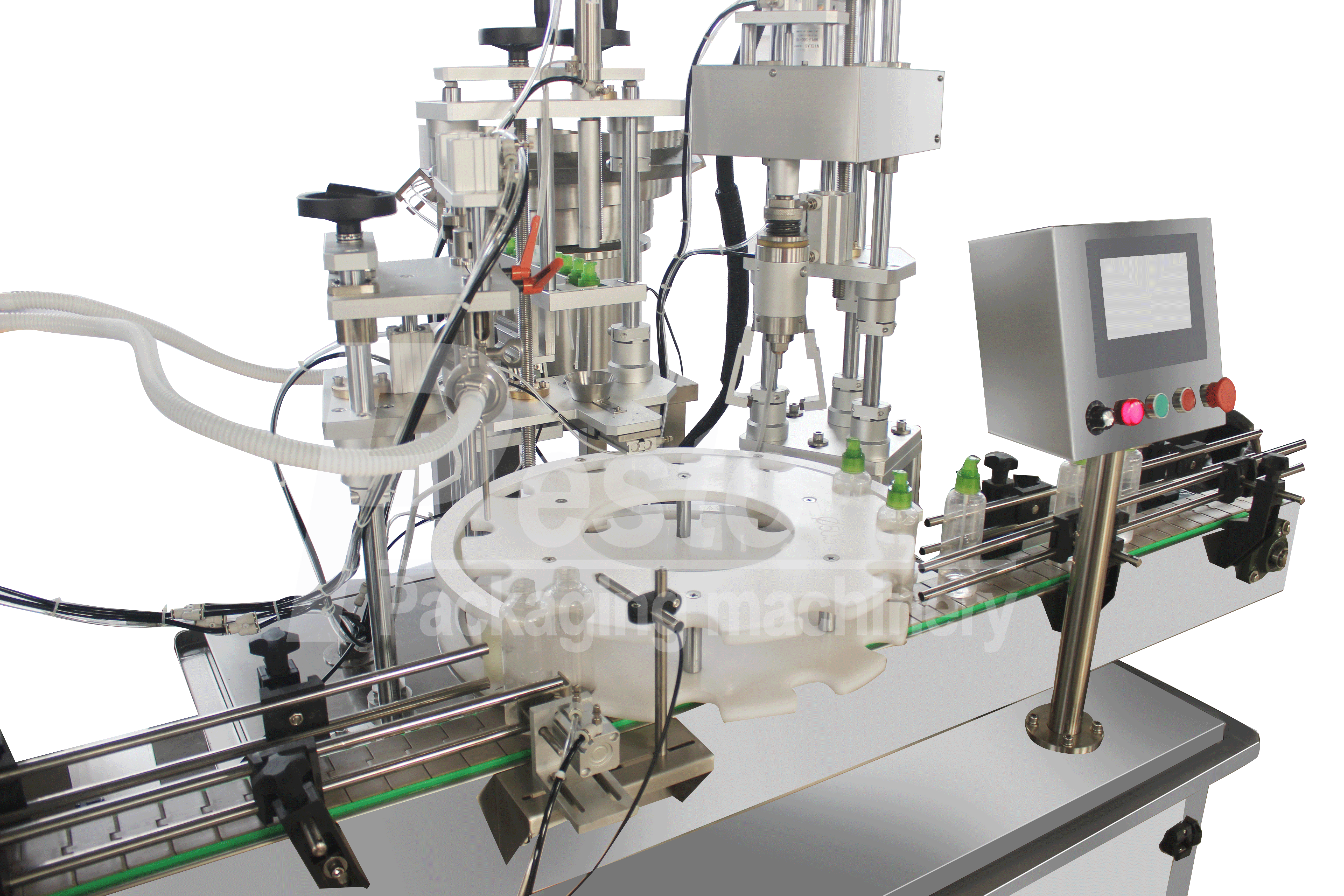

PRINCIPLE OF ESSENTIAL OIL BOTTLE FILLING MACHINE

Our essential oil bottle filling machine and hair oil filling machine integrate state-of-the-art technology with user-friendly controls to provide a streamlined process:

1. Filling

The essential oil filling machine accurately dispenses the desired quantity of essential oil into each bottle, with adjustable settings to accommodate various bottle sizes and fill levels.

2. Capping

Immediately after filling, the bottles move to the capping station, where a precisely calibrated capping system securely seals each container with a consistent and tamper-evident cap.

3. Quality Control

Integrated sensors and controls ensure that only correctly filled and capped bottles proceed down the production line, reducing waste and maintaining product integrity.

HOW OUR ESSENTIAL OIL FILLING MACHINE FIT YOUR PRODUCTS

Revolutionize your essential oil bottling process with our cutting-edge essential oil filling machine and hair oil filling machine. Designed to optimize efficiency and precision, this innovative equipment combines filling and capping in one seamless operation.

Efficiency Redefined

By combining filling and capping into a single operation, this essential oil bottle filling machine significantly reduces production time, labor costs, and the risk of contamination.

Precision and Consistency

Our essential oil filling capping machine guarantees precise filling and capping, reducing product wastage and ensuring uniform product levels and seal quality in every bottle.

Versatility

Our essential oil filling system accommodates various bottle shapes and sizes, making it suitable for a wide range of essential oil products.

Quality Assurance

Built with durable materials and precision engineering, the essential oil filling machine offers long-lasting and reliable performance to safeguard your brand's reputation.

User-Friendly

The intuitive interface makes operation straightforward, requiring minimal training for your staff.

BENEFITS OF ESSENTIAL OIL FILLING MACHINE

Enhanced Productivity

The essential oil filling machine and hair oil filling machine increase your production output and meet growing market demands with this efficient 2-in-1 solution.

Consistent Quality

Ensure that each bottle leaving your production line is filled accurately, sealed securely, and meets the highest quality standards.

Reduced Labor Costs

Our essential oil filling machine automates your bottling process, reducing the need for manual labor and minimizing human error.

Tamper-Evident Seals

Rest easy knowing that your essential oil products are sealed and protected from tampering, enhancing consumer trust.

Customization

Tailor the essential oil filling machine to your specific production needs, whether you're a small batch artisan or a large-scale manufacturer.

TECHNICAL PARAMETERS

Dimension: 1800(L)*1800(W)*2100(H)

Bottle volume: 10-500ml or customized

Power supply: AC380/220V; 50/60HZ

Power: 2.5KW

Air source: 0.6Mpa

Production speed: ≤1500BPH or customized

INTEGRATE A COMPLETE ESSENTIAL OIL FILLING LINE

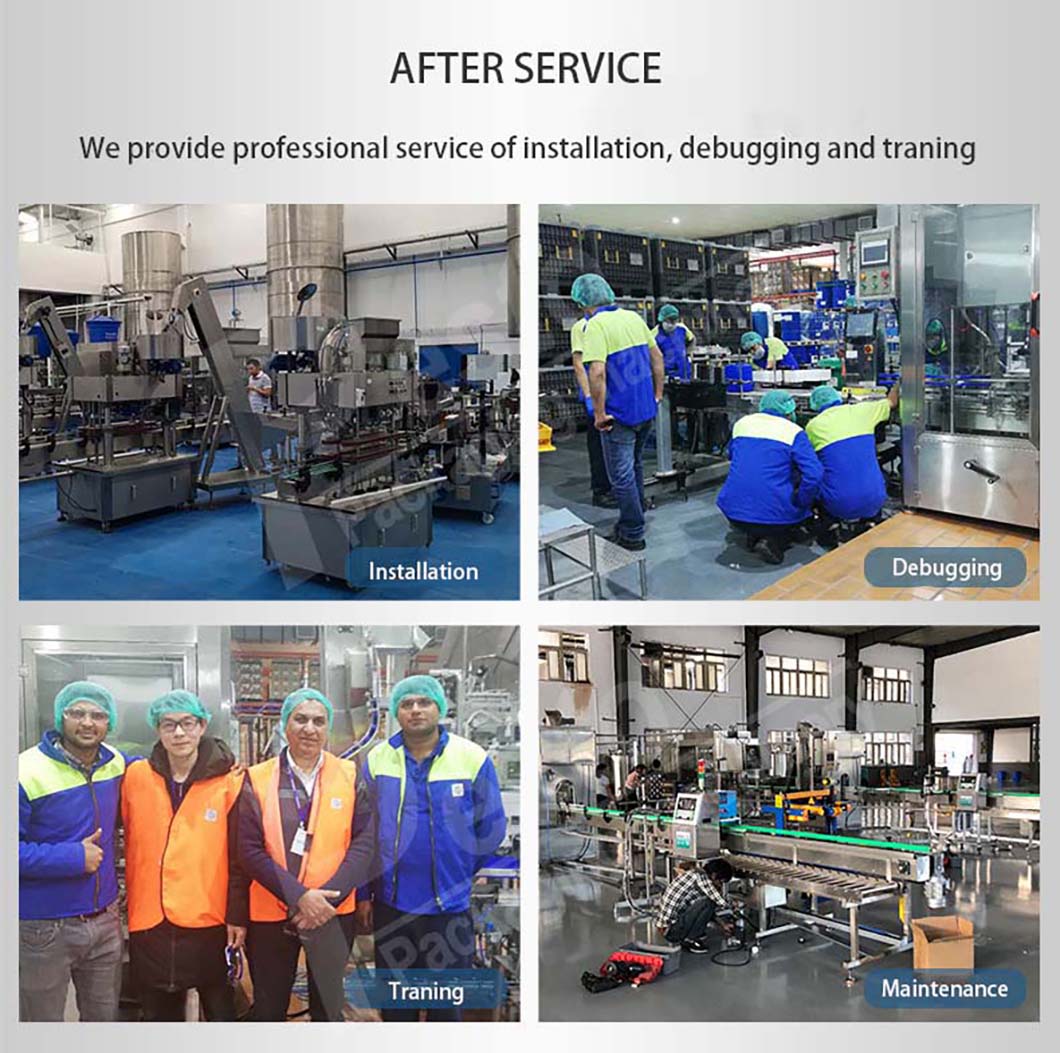

At Pestopack, we’re your trusted partner in the essential oil filling machine and packaging industry. We understand that a seamless production process is crucial to your success, and that’s why we offer complete essential oil filling line integration services. Our expertise and cutting-edge solutions ensure your essential oil bottling operations run smoothly, efficiently, and with the highest quality standards.

1. Filling and Capping Machines

Our state-of-the-art 2-in-1 essential oil filling capping machines are designed for precision and efficiency. Each essential oil filling machine is capable of handling a wide range of viscosities and bottle sizes, ensuring accurate filling every time. Whether you’re working with small artisanal batches or scaling up to large production volumes, our filling systems deliver consistent and reliable results.

2. Labeling and Packaging Equipment

Our integration services go beyond just the essential oil filling machine. We provide advanced labeling and packaging equipment customized to your needs. This ensures every essential oil bottle is labeled with precision and presented attractively, helping your brand stand out on the shelf.

3. Automation and Customization

We know that every essential oil business has unique requirements. That’s why our essential oil filling machines and packaging systems are highly customizable. From small setups to mid-scale production lines, we help you automate your processes according to your specific goals—improving efficiency while maintaining product quality.

English

العربية

Français

Русский

Español

Português

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

қазақ

हिन्दी

فارسی

Kiswahili

українська

Հայերեն

עברית

বাংলা

සිංහල

Oʻzbekcha

Azərbaycan dili

Български

ქართული

guarani

ગુજરાતી

Hausa

Igbo

ಕನ್ನಡ

Kinyarwanda

Kurdî

Кыргызча

Oluganda

മലയാളം

मराठी

Afaan Oromoo

ਪੰਜਾਬੀ

Runasimi

chiShona

Soomaali

Тоҷикӣ

తెలుగు

ትግንያውያን

Türkmençe

Yorùbá

isiZulu