COCONUT OIL FILLING MACHINE APPLICATION

Coconut oil, known for its versatile applications, comes in various forms and viscosities. To meet the specific requirements of different coconut oil products, we offer a range of specialized coconut oil filling machines, each designed to handle various viscosity levels.

1. Low Viscosity Coconut Oil

For thinner, more liquid coconut oil products, we provide precision filling machines optimized to handle low viscosity fluids. These coconut oil filling machines ensure accurate filling for products like cooking oils and light skincare formulations.

2. Medium Viscosity Coconut Oil

Our intermediate viscosity filling machines are ideal for coconut oil products that are moderately thick. These coconut oil filling machines maintain precise filling levels for products like massage oils and hair serums.

3. High Viscosity Coconut Oil

When it comes to thick and highly viscous coconut oil, our specialized filling machines excel. These coconut oil filling machines are designed to handle the challenges posed by dense oils like solidified coconut oil or heavy hair treatments.

4. Customized Solutions

Additionally, we offer customized oil bottle filling machine solutions to accommodate coconut oil products with unique viscosity requirements. Our team works closely with you to ensure that the equipment meets your specific needs.

No matter the viscosity level of your coconut oil product, our oil filling machines are engineered to deliver precise and consistent results. Whether you're in the food, cosmetic, or pharmaceutical industry, we have the right oil filling machine to meet your coconut oil packaging needs.

Piston Filling Machine

Suitable for low and middle viscous coconut oil

Rotary Pump Filling Machine

Suitable for high viscous coconut oil

FEATURES OF COCONUT OIL FILLING MACHINE

Precision Filling

Our coconut filling equipment guarantees precise and consistent filling, maintaining the accuracy of every container.

Versatility

The coconut filler machine accommodates various container sizes and types, offering flexibility for different product lines.

Efficiency and Productivity

Designed for maximum efficiency, it reduces downtime and increases overall production output.

Quality Assurance

Your coconut oil's quality and integrity are maintained throughout the filling process.

Customization

We offer flexibility to tailor the coconut filling machine to your specific requirements, ensuring seamless integration into your production process.

TECHNICAL PARAMETERS OF EDIBLE OIL FILLING MACHINE

Filling heads | 4 | 6 | 8 | 12 |

Production speed

(bottles/hour) | 1L:1000,5L:800 | 1L:1800,5L:1200 | 1L:2200,5L:1600 | 1L:3500,5L:2800 |

Filling accuracy | 1-5L:±5ml |

Filling range | 100-5000ml |

Suitable bottles | Round barrel:height:100-320mm;diameter:Φ100-180mm

Drum: length:100-200mm;width:40-80mm;height:150-300mm

Neck diameter:≤Φ30mm |

Power | 3KW | 3KW | 4KW | 5KW |

Power source | 220/380V 50/60Hz |

Air source | 0.6Mpa |

Dimension(mm) | 1600×1100×2200 | 2000×1100×2200 | 2400×1100×2200 | 2600×1500×2200 |

BENEFITS OF COCONUT OIL FILLING MACHINE

Piston Filling Machine

Suitable for low and middle viscous coconut oil

Rotary Pump Filling Machine

Suitable for high viscous coconut oil

Enhanced Product Quality

Your coconut oil remains pure and consistent with the precise performance of our advanced coconut oil filling machine. Designed with hygiene and accuracy in mind, it guarantees product integrity from the first bottle to the last.

Increased Efficiency

Streamline your production process, reduce manual labor, and boost overall output with an automated coconut oil filling machine. By integrating high-speed filling technology, you can achieve greater productivity while maintaining accuracy.

Versatile Operation

Easily adapt to changing container sizes and types. Our coconut oil filling machine accommodates a variety of packaging formats, making it the perfect solution for businesses managing multiple product lines.

User-Friendly

Simplify operations, minimize errors, and reduce training time with an intuitive interface. Our coconut oil filling machine is designed for ease of use, ensuring smooth performance even for operators with minimal experience.

Cost Efficiency

Lower labor costs and minimize product wastage with reliable automation. The coconut oil filling machine delivers consistent filling volumes, helping you reduce losses and increase profitability.

Our coconut oil filling machine is the solution you need to elevate coconut oil production. Whether you’re a small-scale producer or a large manufacturing facility, this equipment ensures precision, reliability, and excellence in coconut oil packaging.

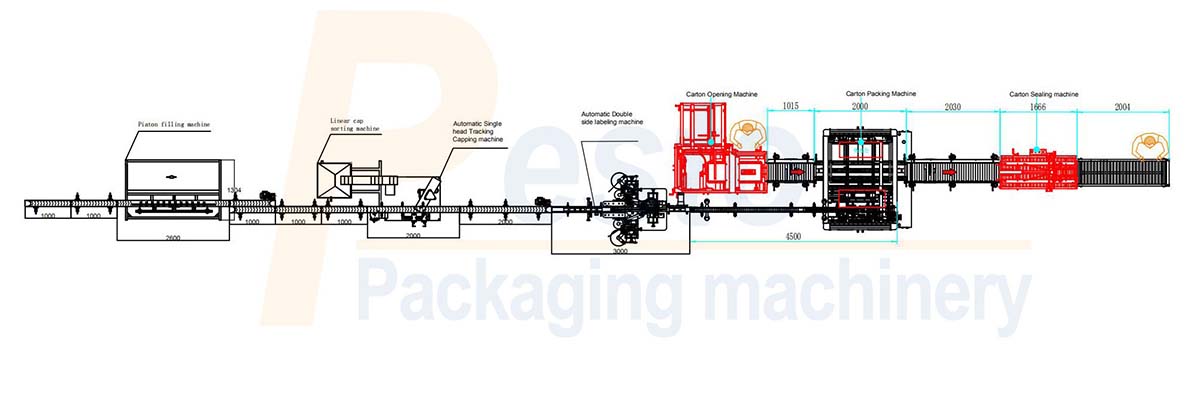

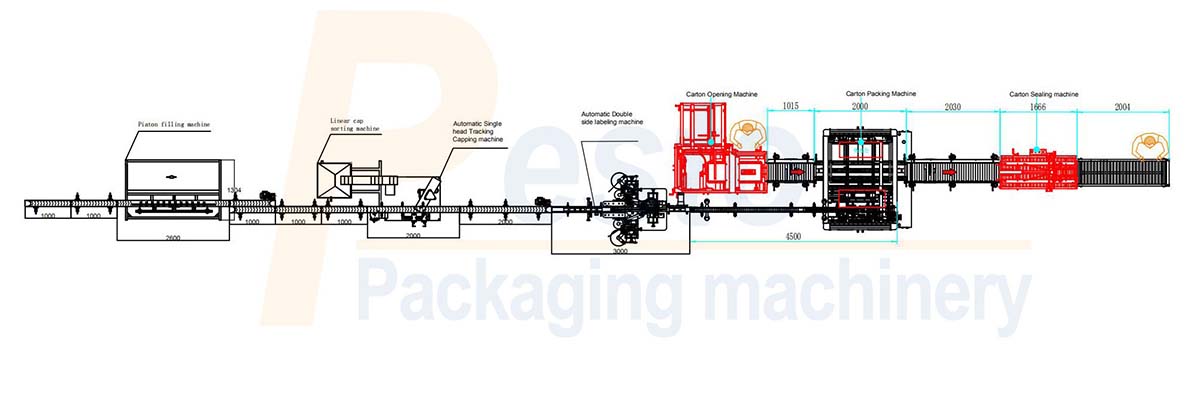

INSTALL A COMPLETE COCONUT OIL FILLING LINE

Pestopack is your trusted partner for seamlessly integrating a complete coconut oil filling line. A coconut oil filling line is a fully integrated system comprising a series of machines and equipment designed to efficiently fill, cap, and label coconut oil containers. This turnkey solution ensures precision, consistency, and productivity throughout the packaging process. With years of experience in the packaging and filling machinery industry, we understand the unique requirements of coconut oil manufacturers. We work closely with you to design a coconut oil filling line that suits your product range, container sizes, and production capacity. Our integrated systems are designed to optimize your production process, reducing labor costs and increasing output.

The Pestopack Coconut Oil Filling Line Integration Process:

1. Consultation: We begin by understanding your specific requirements and production goals.

2. Design: Our experts design a customized coconut oil filling line, considering factors such as container sizes, filling precision, and labeling requirements.

3. Manufacturing: We manufacture the necessary equipment with precision and quality assurance in mind.

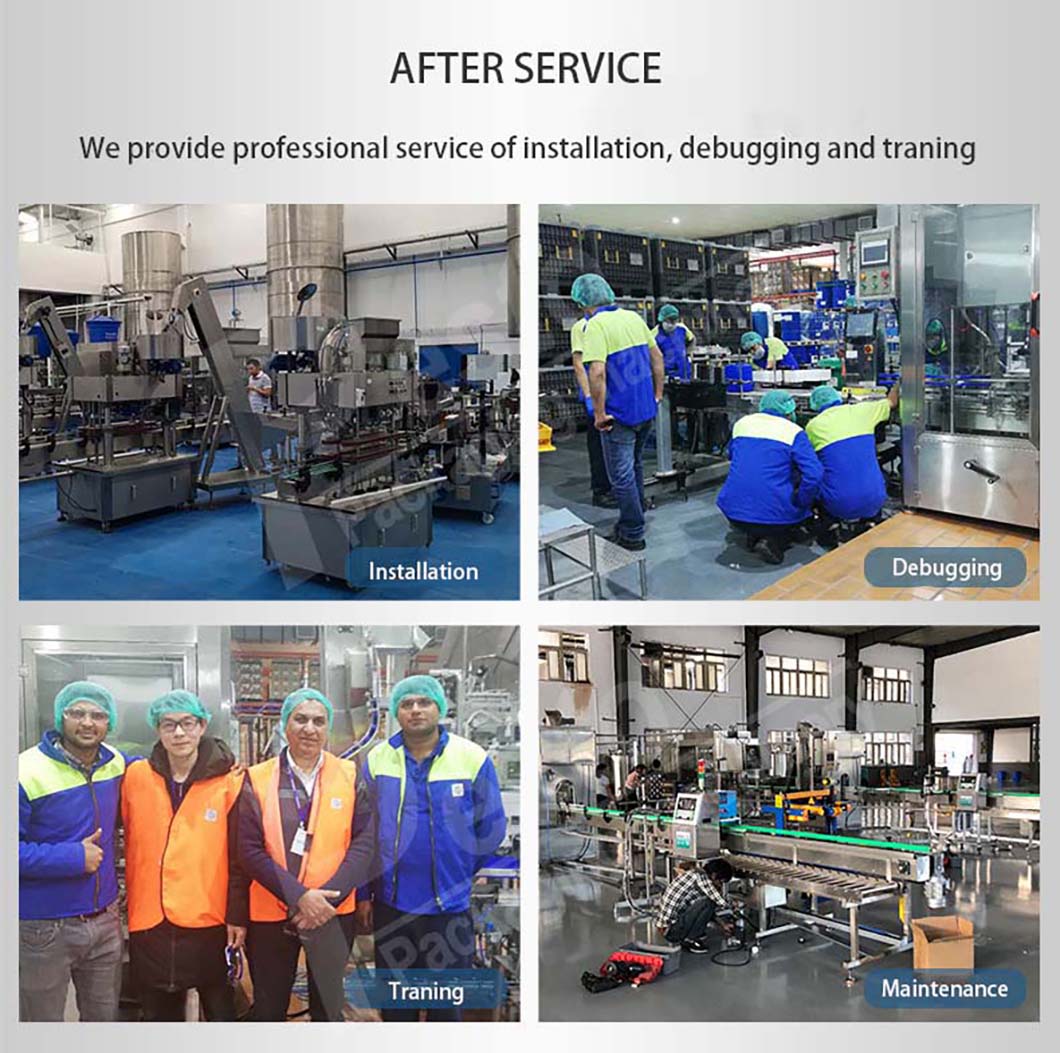

4. Installation: Our team installs and integrates the entire system into your production facility.

5. Training: We provide comprehensive training to your staff to ensure smooth operation and maintenance.

6. Support: Pestopack offers ongoing support and maintenance services to keep your production line running smoothly.

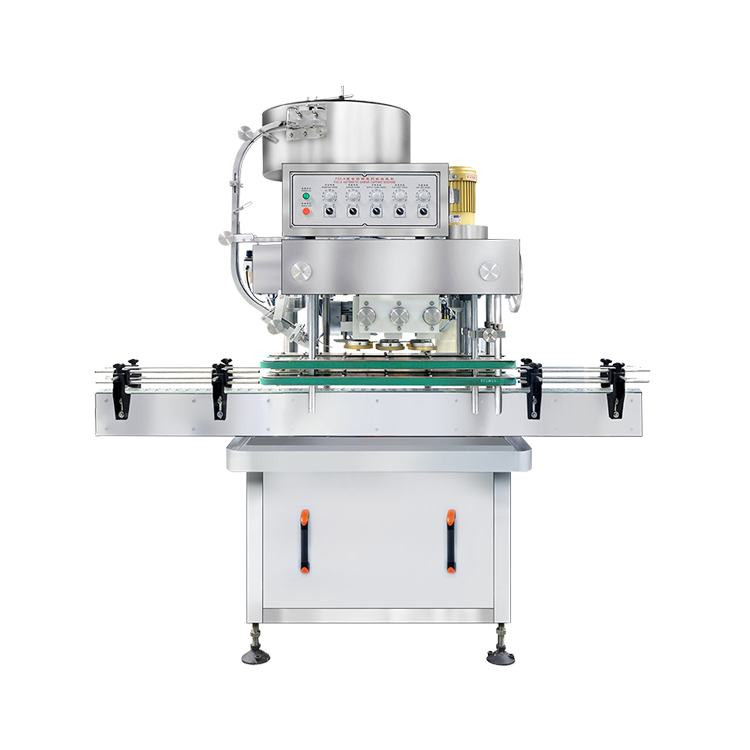

Coconut Oil Capping machine Selection

Coconut Oil Labeling Machine Selection

English

العربية

Français

Русский

Español

Português

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

қазақ

हिन्दी

فارسی

Kiswahili

українська

Հայերեն

עברית

বাংলা

සිංහල

Oʻzbekcha

Azərbaycan dili

Български

ქართული

guarani

ગુજરાતી

Hausa

Igbo

ಕನ್ನಡ

Kinyarwanda

Kurdî

Кыргызча

Oluganda

മലയാളം

मराठी

Afaan Oromoo

ਪੰਜਾਬੀ

Runasimi

chiShona

Soomaali

Тоҷикӣ

తెలుగు

ትግንያውያን

Türkmençe

Yorùbá

isiZulu