VIDEO OF BRAKE OIL FILLING MACHINE

Our oil filling machine is precise, efficient, and excellent in the automotive lubricant industry. Watch the video below for a quick glimpse of what our brake oil filling machine can do.

FEATURES OF BRAKE OIL FILLING MACHINE

Our brake oil filling machine is engineered to revolutionize your brake oil production line. With cutting-edge technology and precision craftsmanship, our brake oil filling system ensures accurate and efficient filling of brake oil in a variety of containers. Whether you are an established manufacturer or a startup, our brake fluid filling machine is the ideal choice for your needs.

Precision Filling

Same like edible oil filling machine, achieve precise fill levels consistently, reducing product wastage and ensuring optimal engine performance.

Versatility

Our brake oil filling machines accommodate various bottle sizes and oil viscosities, providing flexibility for your production requirements.

Speed and Efficiency

Experience rapid filling without compromising accuracy, maximizing your production output.

Reliability

Built to last, our brake oil filling equipment is constructed with durable materials and backed by our commitment to quality.

TECHNICAL PARAMETERS

Filling heads | 4 | 6 | 8 | 12 |

Production speed

(bottles/hour) | 1L:1000,5L:800 | 1L:1800,5L:1200 | 1L:2200,5L:1600 | 1L:3500,5L:2800 |

Filling accuracy | 1-5L:±5ml |

Filling range | 500-5000ml |

Suitable bottles | Round barrel:height:100-320mm;diameter:Φ100-180mm

Drum: length:100-200mm;width:40-80mm;height:150-300mm

Neck diameter:≤Φ30mm |

Power | 3KW | 3KW | 4KW | 5KW |

Power source | 220/380V 50/60Hz |

Air source | 0.6Mpa |

Dimension(mm) | 1600×1100×2200 | 2000×1100×2200 | 2400×1100×2200 | 2600×1500×2200 |

| Production capacity and filling volume can be customized |

APPLICATIONS AND INDUSTRIES

Our brake oil filling machine is versatile and suitable for various industries, including:

Automotive

Industrial Lubricants

Oil Refineries

Chemical Manufacturing

And More

BENEFITS OF BRAKE OIL FILLING MACHINE

Precision Engineering

Our brake oil filling machines are engineered for accuracy, ensuring each bottle is filled to the exact specifications.

Enhanced Productivity

Experience a dramatic increase in productivity and a reduction in downtime, resulting in higher profitability.

Cost-Effective

Efficient filling and minimal wastage translate to cost savings in the long run.

Reliable Performance

Count on our brake fluid oil filling machine to consistently deliver, even in high-demand production environments.

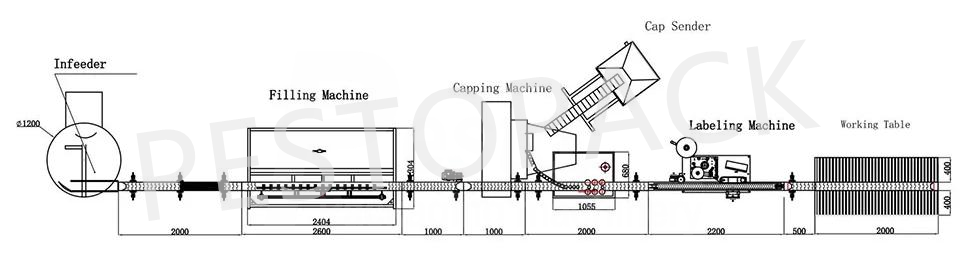

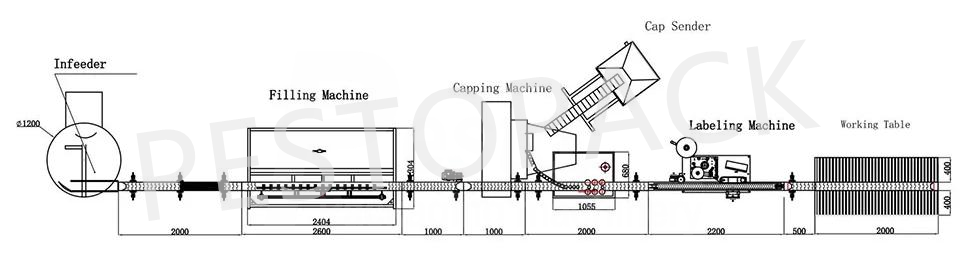

INTEGRATING A COMPLETE BRAKE OIL FILLING LINE WITH PESTOPACK

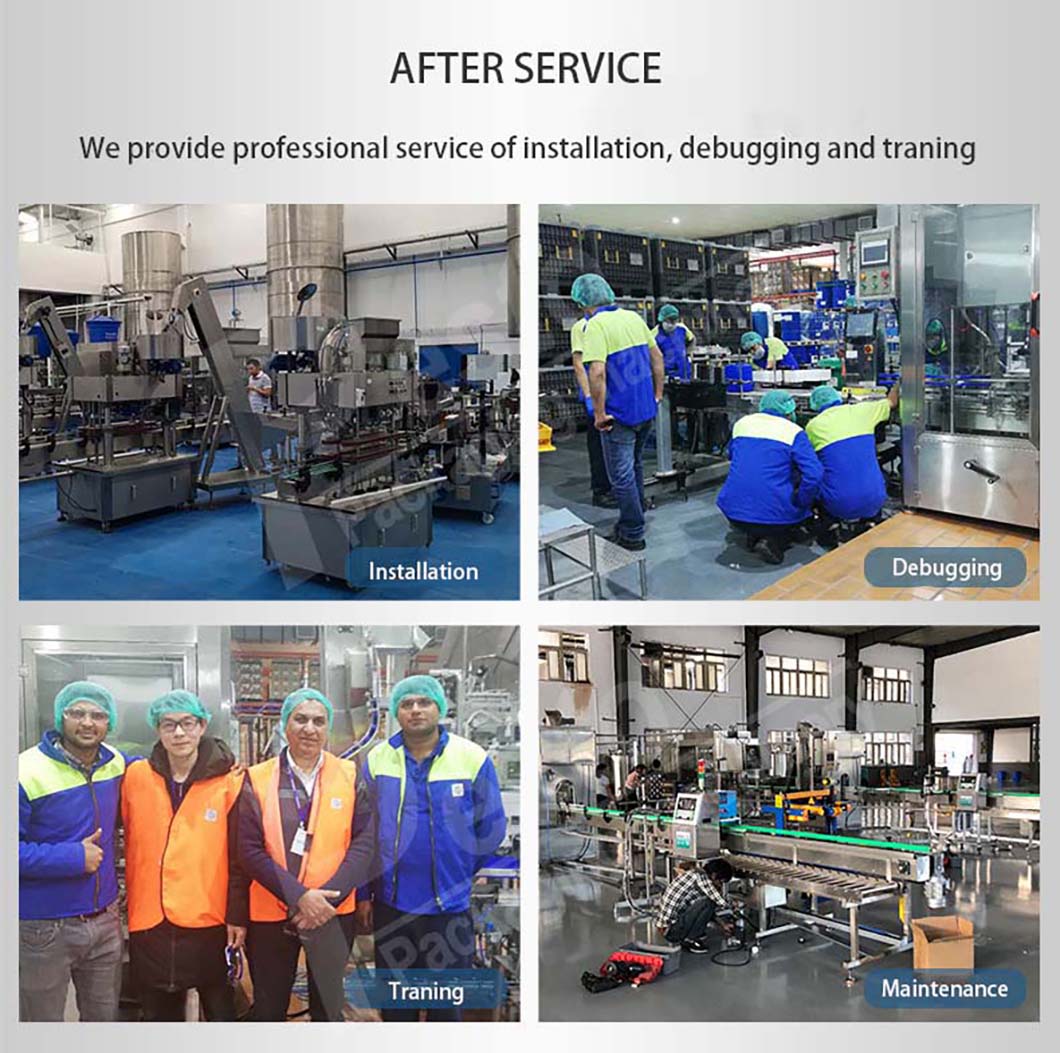

We specialize in providing innovative solutions for your brake oil production needs. Our expertise extends beyond individual machines; we can integrate a complete brake oil filling line tailored to your specific requirements.

A complete brake oil filling line offers numerous advantages, including:

1. Efficiency: Integrated systems minimize manual handling, reducing labor costs, and increasing production speed.

2. Consistency: Precise coordination between machines ensures uniform filling, reducing product wastage.

3. Quality Control: Monitoring and control systems enhance product quality and consistency.

4. Cost Savings: Integration optimizes resource utilization and lowers operational costs in the long run.

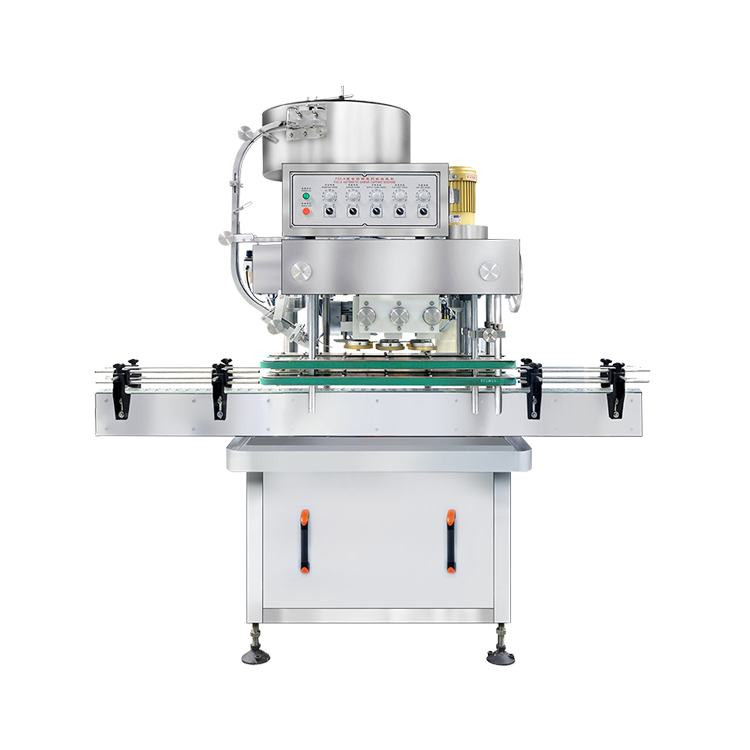

Brake Oil Capping machine Selection

Brake Oil Labeling Machine Selection

English

العربية

Français

Русский

Español

Português

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

қазақ

हिन्दी

فارسی

Kiswahili

українська

Հայերեն

עברית

বাংলা

සිංහල

Oʻzbekcha

Azərbaycan dili

Български

ქართული

guarani

ગુજરાતી

Hausa

Igbo

ಕನ್ನಡ

Kinyarwanda

Kurdî

Кыргызча

Oluganda

മലയാളം

मराठी

Afaan Oromoo

ਪੰਜਾਬੀ

Runasimi

chiShona

Soomaali

Тоҷикӣ

తెలుగు

ትግንያውያን

Türkmençe

Yorùbá

isiZulu